Making with Mycelium: Mushroom Madness

Summary

The mushrooms we see on our dinner plates, or growing in the lawn are actually only a very small part of the fungus that produces them. What we know as mushrooms are actually the reproductive parts of the organism, a bit like the flowers in your garden. Instead of seeds, fungi reproduce by way of microscopic spores, released in their millions from the fruiting bodies and spread by wind or water. You can see this by placing a ripe mushroom cap on a sheet of white paper for a few days (which will leave a ghostly imprint where the spores are released), or even in the wild if ever you squeeze a puffball and a cloud of brown spores results.

Fungi exist as extensive tangles of one-cell wide threads called hyphae that grow through whatever it feeds on - something like the roots of a plant. The interconnected net of hyphae that make up the greatest part of the body of a fungus is called a mycelium. These mycelia can be very extensive - the mycelium of a honey fungus growing in the mountains of Oregon is estimated to be 3,8km in diameter, making it the largest organism on the planet. And just like a flowering plant, the hidden mycelium can persist from year to year, only producing fruiting bodies when weather conditions are right for the spores they produce to be dispersed and grow. This is what makes the fairy rings you sometimes see in lawns that reappear year after year, a bit bigger each time as the edge of the underground mycelium grows outwards.

While fungi growing through tree stumps exude digestive enzymes that gradually make the solid wood weaker, and eventually powdery, the mycelia growing through a looser material (like sawdust or compost) can have the opposite effect, and bind the coarse particles into a solid cake of half-digested material and mushroom mycelium. A skin of mycelium also tends to form around the outside of the food source, binding the material even more.

Innovators are exploring these unique properties of fungi to develop new materials for making useful objects, using no more than waste cellulose (like sawdust, or coffee grounds), a starter culture of fungus (known as spawn) and some environmental control (mushrooms need water and oxygen from the air, as well as a suitable temperature for best growth).

Activity Summary

This workshop uses commercially available mushroom spawn, waste cellulose and moulds made from recycled plastic to introduce participants to the techniques for growing three dimensional objects.

These techniques were developed and trialled at The Edge by Peter Musk, and delivered at the Woodford Folk Festival in 2017 and 2018 in collaboration with Dr Sandra Tuszynska.

Materials

Oyster Mushroom spawn can be obtained from commercial sources (or maybe your neighbourhood mushroom farm). Avoid using the button mushrooms which are the most common commercial variety - these grow on rotted animal manure as a food source, and this material is not only hard to find, but difficult to keep sterile without treatment. Varieties which use cellulose as a food source, such as Oyster mushrooms (of any colour) are preferred, and commercial varieties also tend to grow fast.

Other wood fungi have been investigated, including native forms found on rotting treestumps, but growth is very slow. Varieties found in nature may also have the unfortunate ability to colonise and grow in human nasal cavities, so sticking with Oyster mushrooms is your best approach unless your mycological knowledge is well developed.

Growth medium can be any clean source of cellulose, Coarse sawdust, coffee grounds and even shredded paper will suffice. Using material with large particles (like sugar cane mulch) can make it difficult to pack into the mould if fine detail is desired. Adding a tablespoon of flour (from any source) for each litre of growth medium will speed the process, but is not essential.

Sterilising the growth medium will reduce the chances of contamination ruining the product, but this may be difficult if large volumes are required. A domestic pressure cooker will do the job (90 - 120 minutes at 15psi) but these devices have safety issues, so be sure to follow instructions (and don't run out of water). Liquid sterilising treatments run the risk of killing your fungus, and are best avoided without trials. We have used unsterilised media, and just sterilised the moulds and mixing bowls with success, but expect some losses due to contamination.

Sterilising agent will be used to wipe down any container or form that will come in contact with the spawn. Isopropyl alcohol or methylated spirits is recommended because it can be wiped on, and will dry quickly.

Water to wet the growing medium

OPTIONAL

Plastic sheet for use making moulds with the vacuum former. Adequate material can be recovered from clean, dry 2L milk containers (an approximately A5 sized sheet can be cut from each one). Other thin (0.5 - 1.0 mm) thermoplastic sheet material could also work, such as PET or polypropylene.

Tools

Moulds to hold the material as the mycelium grows. These could be plastic bowls or containers, or moulds made using a vacuum former and an appropriate form.

Large mixing bowls or plastic buckets to mix the growing medium and spawn in.

Plastic bag to use as a sterile growing chamber for the filled mould.

OPTIONAL

A5 vacuum former to make unique moulds on prepared forms. You can see how to make one of these here: A4 / 5 & 6 Vacuum Formers

Forms to use with the vacuum former. These could be an existing object (such as a ceramic bowl or glass jar), a 3D printed, plaster filled form or a shape moulded from clay or plaster. More detail about design constraints for use with the vacuum former can be found in the link above.

Stapler to clip the plastic mould parts together.

Instructions

Step One: Prepare The Moulds

Using Existing Objects

You can use a single mould, and press the growing medium into the shape, or two moulds that fit together. As the mycelium grows, it will form a smooth, white surface against the mould, so if one mould is used, the inside surface will be rough (as you can see in the pictures above).

A simple bowl can be made using two containers of the same size, with a 5 - 10mm layer of growth medium pressed between them. Expect a gap at the edge where the containers meet.

Alternatively, custom moulds made to fit snugly together can be made (or found), which will reduce the gap, and so the risk of contamination.

Using a Vacuum Former

A vacuum former allows you to make custom moulds using your own forms. The form may be an existing object, a 3D printed shape or something made from plaster or even wood. The process involves heating to melt the plastic making the mould, though, so your object needs to be able to withstand this treatment. The object also needs to be sturdy enough to withstand the pressure applied when the vacuum is engaged - testing is recommended. Hollow objects can be filled with plaster to provide extra strength.

You can see the steps in this process below:

Step Two: Assemble the Growing Medium

Commercial mushroom spawn will come as a block of sawdust or rice hulls, covered with a thin layer of silky white mycelium. Inside the block, the distributed hyphae may be less visible. The spawn will probably be inside a plastic bag to prevent contamination and stop it drying out, so leave it there until the rest of your bulk medium is ready for inoculation.

Oyster mushrooms will grow on any source of cellulose, and we have used coffee grounds, shredded office paper and a mixture of both. Avoid shiny paper with lots of ink (like junkmail catalogues or glossy magazines) because some inks could be toxic to the growing fungus.

Coffee grounds have the advantage of already being heat sterilised, but they are a rich source of nutrients, so you need to use them within a few days of collection or contamination becomes a problem.

Sawdust or wood shavings could be used, provided they do not come from treated timber. Wood shavings sold for lining pet cages are usually chemical free, but something from a wood-working factory runs the risk of being contaminated with sawdust from particle board, plywood or MDF. and these manufactured products contain lots of potentially toxic glue. On the other hand, if you do find a fungus that can digest the formaldehyde riddled manufactured wood products, you might have solved one of the great recycling challenges of our time.

Commercial growers traditionally use rice hulls, and unprocessed wheat bran would be an equivalent material that is available from the supermarket.

Adding a tablespoon of plain flour (from any source) to each litre of the cellulose material will speed fungal growth, but this is not essential.

WHY?

Flour is mostly composed of powdered starch, and starch is a polymer of the glucose molecules that are the ultimate food source for the fungus. While cellulose is also made of glucose molecules (though chemically linked in a different way), starch is easier to break down, and so the fungus gets a rapid sugar hit to jump start growth.

Step Three: Mix the Medium

Sterilise a bucket or large bowl using isopropyl alcohol to wipe down the surfaces. Allow this to dry before filling with enough growing medium to fill your mould(s).

It might be worthwhile to wear sterile gloves, or at least wash your hands thoroughly before the manual mixing to follow.

Add enough water to make the medium wet, but not sloppy. Excess water will seep to the bottom of the container, but too much makes for a messy experience. Crumble the spawn into the material, and mix thoroughly with your hands. The more you break up the spawn, the better the mixing, The material needs to stay in a ball when you squeeze a handful - without more than a few drops of liquid dripping out.. More water will make it stick together if it is still too crumbly.

The ratio of spawn to medium is not too critical - but the more spawn in your mix, the faster the mycelium will grow throughout the object. We have used a ration of spawn to material about 1:5. Faster growth will reduce the chance of contamination overtaking the fungus, but this depends on how much spawn you have, and how many things you plan to make.

Unused spawn can be re-sealed and stored in a refigerator for up to a month without losing too much vitality.

Step Four: Pack the Moulds

Using clean hands (or wearing gloves) pack the wet mixture into your mould.

For a thin walled object (like a bowl or cup), press the material onto an outer mould, to a thickness of about 5mm. This is easier if the material is fine grained (like coffee grounds), or at least well watered (like shredded paper). The inner mould can then be pressed firmly into the cavity, and any holes that appear can be repacked if necessary.

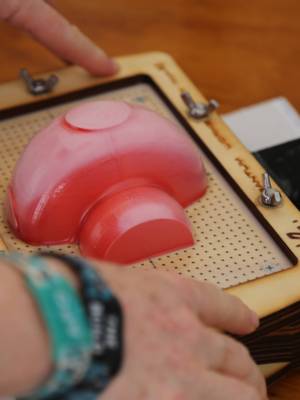

For a 3 dimensional object (like the mushroom pictured), pack each half of the mould , and them bring them together.

Step 5: Close the Moulds

Moulds vacuum formed from sheet plastic can now be stapled together around the edges.

The object is then put into a plastic bag, and sealed to prevent contamination. Wrapping in clingwrap could also work.

Step 6: Growing Conditions

Fungi need moisture and oxygen (from the air) as well as a food source to grow. Since growth may take several days (even a few weeks if the spawn was diluted a lot) this means that opening the bag and spraying with water every few days will be necessary. Take care to use clean hands, and leave the object exposed to the air as little as possible to avoid contamination. You can put some small holes in your plastic mould to help with the air exchange too, but this does increase the risk of contamination.

Keep the object in a dark, humid place, and if possible maintain a temperature of 20 to 30C.

Patience is required, but you should be rewarded with an expanding white mycelium appearing on the outside of your object in a week or so. the longer you allow growth to continue, the stronger your product, but after several months, the fungus will completely digest the food material, and a squishy mess might result.

Step 7: Preservation

When you are satisfied with your creation, and are ready to pop it out of the mould, you can put the object (without the plastic mould) into a oven at 180C for 15-20 minutes to kill the fungus, and halt growth. Sealing with a wood coating like polyurethane will help preserve the object, and improve water resistance.

If you want to actually grow mushrooms on your object, then do not use heat sterilisation. Different mushrooms respond to different triggers that initiate fruiting - for oyster mushrooms, increased humidity, a bit more light and lower temperatures (10 - 15C) all increase fruiting. You can expect to get a few crops in successive waves over several weeks.

Troubleshooting

Contamination in the form of green or black mould is the most common problem. Even commercial growers expect 10% loss due to these ubiquitous microbes. Spot sterilisation with isopropyl alcohol or methylated spirits will kill the invader, but this also kills the fungus growing in the immediate area. Practice, sterilising your growing medium and using good hand cleanliness is the best approach. Making your objects in a cleaned room will also help.

References

Mushroom growing has become a popular hobby, and there are many websites only a Google away with more information.

Using mycelium to make biodegradable packaging and wall insulation has been pioneered by Ecovative Design, and you can read about their success here: https://ecovativedesign.com/.

Very few wild species of wood fungus have been trialled in this process, but if you are interested in doing some Citizen Science, take care that what you grow is not a health risk. The following might assist in identifying any wild fungi you find in the Australian bush: http://www.fungioz.com/fungioz-app.html https://fungimap.org.au/