Breeze Blocks 2022

Acknowledgement

We acknowledge Aboriginal and Torres Strait Islander peoples and their continuing connection to land and as custodians of stories for millennia. We respectfully acknowledge the land on which we all meet today, and pay our respects to elders past, present and emerging.

Summary

The following procedure will use a breezeblock design similar to Austral Masonry’s 15-937 Wedge Breeze as an example.

These notes will guide you through the process of designing your breezeblock, making the mould you will use for casting the block, mixing the concrete, pouring the block, and extracting the block from the mould once the concrete has set.

Background

Breezeblocks have historically been made from concrete, clay, or mud. They have been popular in tropical and subtropical climates where a combination of ventilation and privacy are valued. Breezeblocks have appeared in Brisbane architecture over the decades. A search of the 61,000 images comprising the Frank and Eunice Corley Collection Corley Explorer (slq.qld.gov.au) held by the SLQ returns a total of 387 images tagged with the term ‘Breezeblocks’. The photographs were taken by the Corleys all around Queensland during the 1960s–70s.

Skills Introduced

- Concept development

- Vector drawing

- Fabricating with polystyrene foam and concrete

Materials and Tools

Preparation

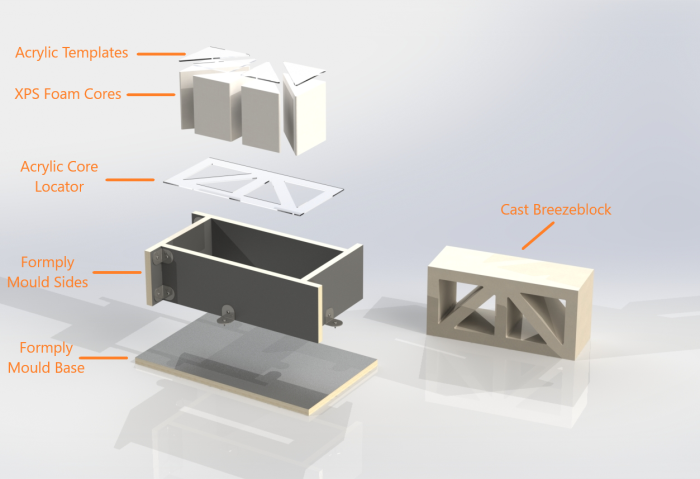

Formply will be used to make the mould box which defines the outside faces of the block. All outside faces will be cast against the Formply except the upper face, which will be open to the air and levelled using a trowel. For safety reasons, your facilitators will supply all Formply mould components cut to size and ready for your use.

All inside faces of the block will be formed against XPS foam inserts or cores. You will receive instruction on how to cut the foam using a hot wire. Because the XPS foam sheets are not readily available in a thickness corresponding to the full depth of a breezeblock, you will need to glue 2 or 3 thicknesses in a sandwich.

Session One

Inspiration

Inspiration from Corley Explorer: https://explorer.corley.slq.qld.gov.au/ (explain what this is and how to search for breezeblocks)

Overview

In this 1st session, you will design your breezeblock (including finalising its overall dimensions), prepare the vector artwork, use this artwork to cut acrylic templates on the laser, cut your oversize XPS foam core blanks on the hot wire, and glue up the stacked blanks using the Hot Wire Foam Factory Fusion Glue. As the Fusion Glue can take a week or more to fully dry, you won’t cut the blanks to their final shape on the hot wire until the next workshop session.

Designing Your Breezeblock

Your 1st task is to design your breeze block. The Wedge Breeze measures 390L x 190H x 140mmD, but breezeblocks have been made—and continue to be manufactured—in other proportions. Austral Masonry also produces designs in the following sizes:

390L x 190H x 90mmD

290L x 290H x 90mmD

Like the Wedge Breeze, your design can be a simple extruded form, or it can feature pockets to add additional visual interest. For inspiration, search the Corley Collection and the web to see past examples and current trends. We will work with you to ensure what you design can be cast successfully. You will draw your design in a vector graphics drawing program. Both CorelDraw and Inkscape programs are available on the supplied laptops for your use.

Drawing & Laser-Cutting Your Breezeblock

You will need to draw your design at full size using either CorelDraw or Inkscape software. If you are unfamiliar with these programs, don’t worry—your facilitators will provide all the assistance you need. When your drawing is ready, we will import it into a program called Ruby. Ruby is the software that communicates with our Trotec laser cutters. Your facilitators will work alongside you to laser-cut your breezeblock profile in 3mm clear acrylic sheet. Don’t discard any of the cut pieces, as you will use some shapes as templates when cutting your XPS cores on the hot wire, and the primary profile as a guide for accurately locating your cores in the mould cavity.

Cutting the XPS Foam ‘Cores’

We will have 2 Proxxon Thermocut hot wire cutters available for cutting your XPS foam ‘cores’. These devices pass an electric current through a thin, vertical NiChrome wire that extends up through a table to an overhead arm. The resistance heats the wire to a temperature that enables it to melt through the foam as the sheet is slowly and gently pushed past the wire. The cutters have the capacity to cut foam up to 140mm thick. To get a feel for how they work, you should practice on a bit of scrap material. The wire should not bend when feeding the foam through it. If the wire deflects, use less force and feed the foam more slowly. Your facilitators will assist you to adjust the temperature of the wire for the best cut result. Note that, when operating, the wire is hot enough to burn your skin. The wire also remains hot for a period after the current has been switch off. Please take care not to contact the wire with your fingers. Melting XPS foam also creates fumes, so all foam cutting will take place with an extractor arm positioned to remove and filter these fumes.

Your facilitators’ experience is that the best surface finish on XPS foam is achieved by cutting cores a few millimetres oversize on the hot wire, followed by sanding up to the acrylic guides with a sanding block. The foam will sand much easier/faster than the acrylic, so don’t be afraid to sand right up to the templates. The larger the sanding block, the better.

If the laminated foam cores protrude above the edge of the mould box, they should be cut flush with the edges using the hand-held hot wire sculpting tool. The hot wire can rest directly on the top of 2 Formply mould box side panels—one placed on either side of the core. The side panels will ensure the foam is cut to a controlled height as the wire is pulled along the “rails”.

Session Two

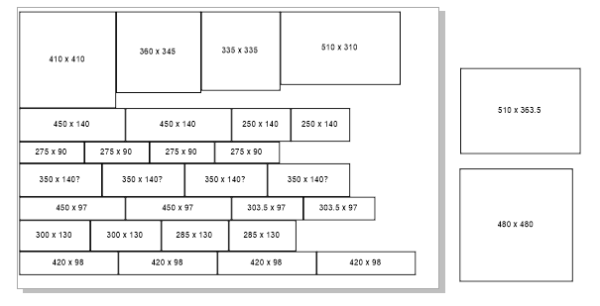

Based on the overall dimensions of your design, your facilitator will have undertaken the following in preparation for this 2nd workshop session:

- All Formply mould box components cut & drilled

- All mould boxes screwed together using metal brackets

- All XPS foam cores cut by hot wire and sanded to final contours using laser-cut acrylic templates

- All XPS foam cores cut by hot wire to internal height of mould boxes

- All XPS foam cores sealed with 1 coat Bounce rubberiser

- All XPS foam cores adhered to either bottom panel or side panels (as appropriate) of mould boxes using UHU Polystyrene Glue

Sheet layout for cutting workshop mould box sides and bases from 1800 x 1200mm panel

In this session you will apply petroleum jelly as a mould release, mix your concrete, pour the mix into your mould, vibrate the mould to encourage bubbles to rise to the surface, and level the pour using a trowel. All concrete measuring, mixing and pouring will take place outdoors on Level 0 of The Edge building, in an area we call ‘the Pit’. Due to the dusty and caustic nature of concrete, P2 dust masks, nitrile gauntlets, and eye protection will be provided. The Pit has running water, but all water used to rinse concrete from buckets, tools, and gloves must be contained on site in the large plastic tubs provided. We recommend you wear clothing you don’t mind getting dusty or splashed. While we don’t have a vibrating table available for encouraging bubbles to rise to the surface of the pour, we propose to put your filled moulds on a flatbed trolley and roll them over a braille trail to remove air bubbles.

Your facilitator will demonstrate removing a previously cast breezeblock from its mould, if one is available.

Sealing the XPS Foam Cores

Concrete will stick to XPS foam if it is not treated with a release agent—but release agents will damage the foam if it isn’t sealed first. We had originally intended to apply Bounce—an ‘All Purpose Foam Coat Rubberizer’ compatible with EPS and XPS foams—to your cores prior to pouring the concrete. When applied by brush, Bounce will strengthen and seal the foam in preparation for later application of a release agent. Bounce is also non-toxic and cleans up with soap and water. Unfortunately, as Bounce takes up to 6 hours to fully dry there is no means to include this step within the time frame allocated to this workshop. Your facilitators will aim to apply the Bounce to as many of your mould cores as time will permit. We include the information about Bounce so you can use it when making additional breezeblocks at home—if that is your desire.

Attaching the XPS Foam Cores to the Mould Box

Your laser-cut acrylic core locator can be used to help position your foam cores within the mould box. The template will also indicate where you need to apply the UHU contact adhesive that will hold your cores in the mould cavity. You will likely need to score-and-snap your acrylic template into smaller “puzzle” pieces to allow easier extraction of these pieces from the mould box once the cores are adhered in place. Always wear cut-resistant gloves when scoring and snapping acrylic. The UHU contact adhesive must be applied to both surfaces to be bonded and allowed to dry for around 10 minutes before bringing the surfaces together. Note that the adhesive does not allow for repositioning once the surfaces make contact. The best positioning technique is to touch one edge of the XPS foam core to the mould base using a piece of the acrylic core locator as a guide. You can then roll the core down onto the base until full contact is made.

Casting your Breezeblock

Working with fast-set concrete requires organisation. A ready source of clean water, all required equipment, and a tool cleaning station should be set up nearby. The concrete must be thoroughly mixed and the mould filled within 5 minutes. Prior to setting (around 15 minutes) the mould should be vibrated to encourage as many air bubbles as possible to rise to the surface. The concrete should also be trowelled smooth before it has set. Once the concrete has set it will no longer be possible to evacuate entrapped air. High-strength fast-set concrete will reach sufficient strength for de-moulding in 3-4 days. Full strength is attained in 28 days.

Session Three

Your concrete breezeblock will take 3-4 days to attain sufficient strength for demoulding. You have the option to extract your breezeblock from the mould yourself during the Saturday Fabrication Lab pop-up session. Alternatively, you can take your mould home and extract the breezeblock there. A 3rd option is to have your facilitators de-mould your breezeblock and set the block and mould components aside for you to collect at your convenience. Let us know your preference. Note that the concrete will take up to 28 days to achieve its full strength.

Extracting your Breezeblock from the Mould

Wait at least 3 days before attempting to extract your breezeblock from the mould. You can wait much longer if desired. Remove and/or loosen enough screws holding the mould box side panels in position so they can come away from the base. Keep track of which panels go where, as the mould box is hand-crafted and will only assembly one way. Once the side panels are removed, turn the bottom panel over and—over a soft pad or similar—see whether you can shake the block from the foam cores. Alternatively, you might place the mould base on the floor, block side up. While holding the base down with your feet, try lifting the block from the foam cores. If these techniques fail, you will need to destroy the foam cores to free your breezeblock.

You are welcome to return to our open lab and/or Hack the Evening sessions to make additional acrylic and/or XPS foam components for use in casting additional breezeblocks.

References

Downloads

slqbreezeblocksworkshop2022.pdf

Rob Wecker Breezeblock https://www.tinkercad.com/things/bcDWWJjiBfv?sharecode=TH2WZ52fBqf3hPqVIiEOC_nefob5B0SehogvrAoDL08

Chloe Haywood Breezeblock #2 https://www.tinkercad.com/things/iJdB8ofaJau?sharecode=bo_F30N_CPYVoLGDMR1wzQnOqV-9oZuxTRQOLU5h77k

Chloe Haywood Superseded Breezeblock https://www.tinkercad.com/things/fOEXA9RkXKj?sharecode=pyiFd-KDzqL9y03UjVGk_bHEH2qHzctSxMOKUFjxzkE

Liz McGuire Breezeblock https://www.tinkercad.com/things/dlI3snZXm9v?sharecode=1aAtk8WqtHShJWsGHF_SkkQlhfcyWF_X1NnMuhcFRZM

Angie Fairweather Breezeblock https://www.tinkercad.com/things/dmIjUFKJud5?sharecode=OXKe8z2s0JQvMrOqT-34G3ZD2nqdA9XA0QLYXJRQaSw

Gael Phillips Breezeblock #1 https://www.tinkercad.com/things/8L9bI5xKA6t?sharecode=Bt0cr_FLpxcZjV79QfxzgJV6lcjV7WW0OSVV4kmHLvU

Gael Phillips Breezeblock #2 https://www.tinkercad.com/things/7mUBiEqHW0o?sharecode=fgF4rKLU0ms4UPZcvE01lrkrsBOuWEURpYT7JSKV5T8

Kerry Forsythe Superseded Breezeblock https://www.tinkercad.com/things/2ozWbXC2k0K?sharecode=WwctzKqArGrk4maKw4N42_PQ6ywHncOVJvODDIprVT4

Kerry Forsythe Breezeblock #2 https://www.tinkercad.com/things/82KeMcpQdOa?sharecode=75m07BTcEQAYapgL_TsaEXdQhkrmxfR4XPa6LBWksgw