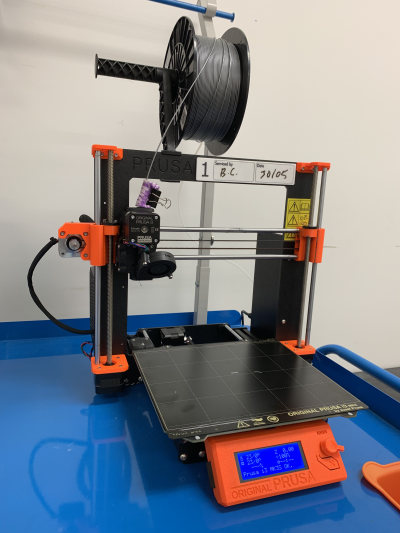

Prusa i3 MK3s+

The Prusa i3 MK3s+ is a successor to Original Prusa i3 MK3 with hardware and software upgrades which lead to improved reliability and ease of use and assembly.

The Prusa i3 MK3s+ is a successor to Original Prusa i3 MK3 with hardware and software upgrades which lead to improved reliability and ease of use and assembly.

The Edge purchased 5 Prusa i3s printers to replace the ageing Up mini 2s.

Summary

- Build volume – (250(W) x 210(D) x 210(H) mm (11,025 cm3)

- 0.4mm nozzle

- PEI print surface

FILAMENT MATERIALS

In theory, the Prusa i3 Mk3s+ can be set up to print using a range of filaments including:

| PLA | Polylactic acid (Starch based) |

| ABS | Acrylonitrile butadiene styrene |

| PETG | Polyethylene terephthalate (Glycol modified) |

| Nylon | Polyamide |

| Composite Materials | Often PLA with carbon fiber, metal or wood fill |

| HIPS | High-impact polystyrene |

| PVA | Polyvinyl acetate (Water-soluble Print support) |

| PP | Polypropylene |

In practice, we control the types of filaments permitted for printing, due to the emissions they produce when melted. For the full range, see: Supported Filaments

Overview

Maintenance

Manual

prusa3d_manual_mk3s_en_3_11.pdf

Elements of this wiki entry have been adapted from the Prusa 3D Manual Mk3S; English Edition, which is published under a CC attribution licence and is available here

Induction Materials

3D printing operations

Below describes guidelines for coordinating public access of the 3D printers.