Health & Safety

Risk Management Framework

Summary

Through The Edge, The State Library of Queensland is committed to providing a welcoming, safe, healthy and sustainable environment for Queenslanders to engage, experiment and learn in the areas of art, science, technology and enterprise.

As part of the State Library of Queensland, The Edge is subject all the organisation’s broader occupational health and safety policies, procedures and governance instruments.

The Edge’s has a particular focus on engaging participants in hands-on experiential learning at the cutting edge of art, science, technology and ensuring its resources and programs are accessible to Queenslanders from a range of backgrounds.

These particular objectives demand a framework of risk management tools beyond the general scope of State Library of Queenslands Occupation Health and Safety policies and procedures. The following documents the policies and procedures that The Edge will undertake in addition to its compliance with State Library's Health and Safety Policies and Procedures and other pertinent governance frameworks.

Legal Underpinnings

Understanding the legal underpinnings of this framework will assist The Edge’s staff in effectively applying the procedures and explaining policies to the public and contractors its contractors.

The Board of the State Library of Queensland, SLQ management and the management of The Edge have legal responsibilities to ensure the health and safety of all staff, contractors and members of the public on site and or engaged in and Edge activity elsewhere. Any process, tool and or materials identified as posing a risk to the Occupational Health and Safety of staff and members of the public, is to be used at the discretion and authorization of The Edge’s management.

The Edge’s managers cannot be everywhere at once however. Consequently management has established a framework of policies and procedures governing the use of identified processes, tools and materials and delegates authority to competent individuals to use, and or supervise use of these. Different levels of authorization are delegated to staff, contactors and members of the public to provide supervision or use processes, tools or materials. The different levels of delegated authority are granted to staff, contractors and members of the public after demonstration of competence in a induction process or via recognition of a formal qualification.

Framework Instruments

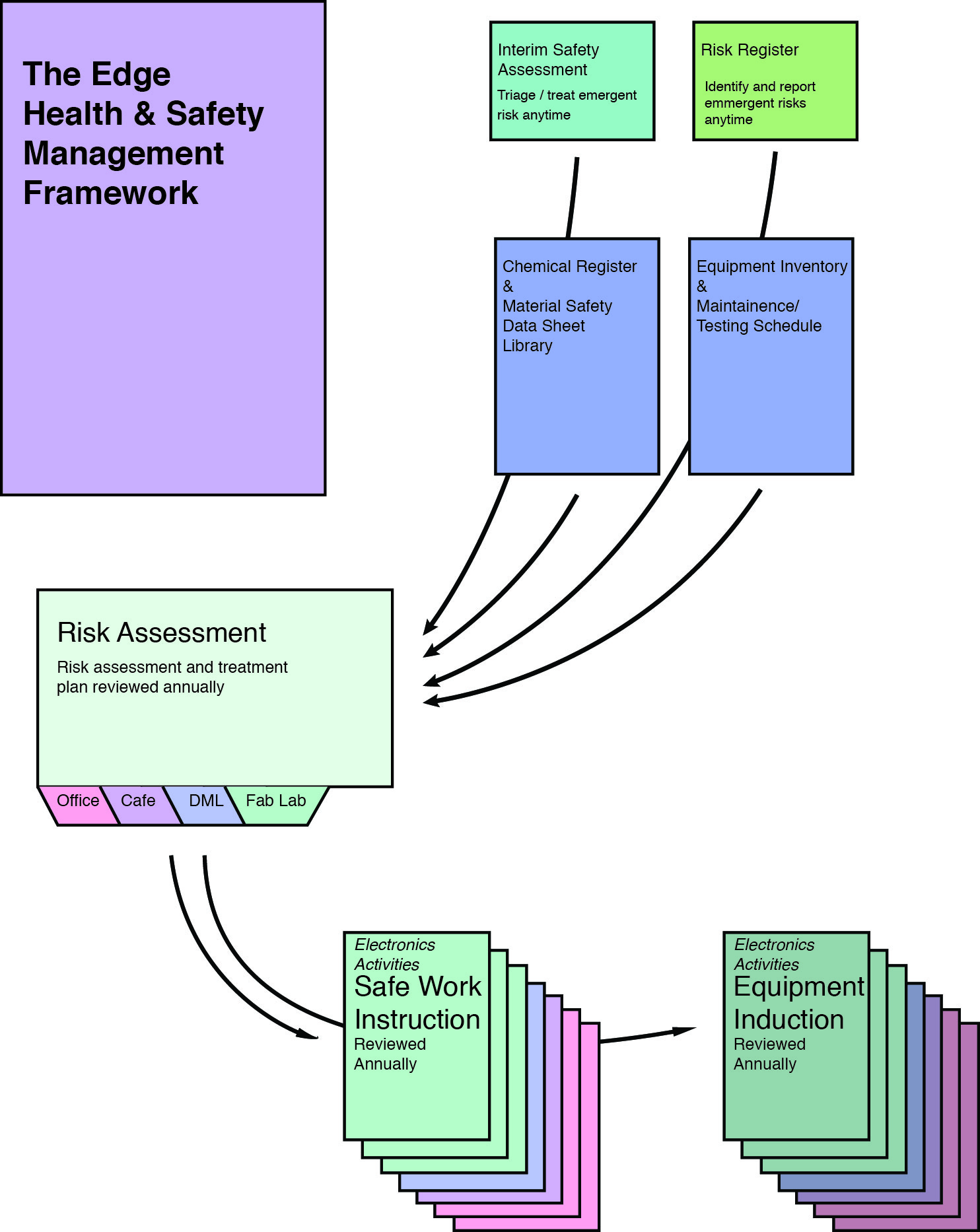

| Instrument | Purpose / Description | Examples of Use |

| The Edge Heath & Safety Framework | ||

| - Risk Assessment Tool | The Edge carries out regular assessments processes and documents the risk associated with the processes, tools and materials used. These risks, their status, treatment review schedules and the delegated owner of this risk are document and monitored in the Risk Assessment Tool. A risk assessment is maintained for each of the work and public spaces in The Edge and may be established for any process, tool or material directed necessary by management. Template, approved process, risk matrix and register of detailed and recurrent, assessments and treatment plans of identified health & safety risks | - Annual Lab 4 risk audit - Risk assessment for a large event like Halloween. |

| - Interim Safety Assessment Tool | Template, approved process, and register of health & safety risks assessments conducted outside of the regular review schedules. | - Use of a new tool, material, process - Risks identified during the course of an activity or project and require assessment immediately |

| - Safe Work Instructions Tool | Template and Library of written guidelines to be observed by all SLQ staff, contractors and members of the public when carrying out specific but regular activities, processes or the use a particular piece of equipment identified as requiring a risk management response. | - Standard Software /Discussion Based Activities - Basic Video Production Activities - Basic Electronics Activities - Basic CNC Milling Activities - Basic 3D Printing Activities - Basic Sewing Activities - Live Production training activities - Creative Community Computing - Kombucha production activities - Activities that involve the use of Biological specimens - Activities that involve the use of hand & Power tools - Activities that occur off site and in Public a public space - Activities that occur at a partner/client or third party space - Parental/Guardian consent for minors participate in activities that include hazardous materials, tool or processes - Needle Stick Injury - Long Distance driving |

| - Workspace/ Process/Equipment Induction Tool | A session plan (and register of successful inductees) designed to teach and assess the assess the competence of Staff, Contractors, Super-users and participants to apply the risk treatment strategies detailed in the various SWIs. | - Sewing Machine/ Overlocker Induction - Hand & Power Tools Induction - General Fabrication Lab Induction - 3D printer Induction - Shapoko Induction - Microscopy Induction - Soldering Induction |

| - Risk Register | A register of health & safety risks identified outside of the regular review schedules. The risk register provides a tool to triage for the most timely response - whether this is within a regularly scheduled cycle or requires immediate out of session action. | |

| - MSDS Library | A Library of MSDS for all materials used in activities at The Edge (audited /updated annually) | |

| - Equipment Inventory & Maintenance Schedule | A complete register of all equipment and tools held by The Edge. Reports will be called up from this register to manage safety testing and maintenance schedules and will be used in an annual stock take /audit. | |

| Linked Policy and Procedures | Fabrication Lab Booking/ Use Policy Fabrication Lab Supervisor Procedure Fabrication Lab Tool Access Policy Fabrication Lab Tool Inductions Laser Material Policy Visitor Services Procedures SLQ Emergency Procedures SLQ Responsible Conduct Procedure SLQ Workplace Health and Safety Policy |

OHS Documentation

These are working documents, and so subject to change and addition.

Induction paperwork

Standard Operation Procedures

These are one page safety reminders made to be laminated and posted adjacent to the tool for ready reference, not a 'quick start' checklist. Mainly for powered equipment.

Safe Work Instructions

These are more detailed operational guides that consider all risks associated with particular activities (including events, driving and other staff related activities)

A general form for developing Safe Work Instructions as used by SLQ is here:

Policies and Procedures

These back-of-house guides cover such things as testing laser materials, disposal of hazardous wastes, working with biological materials etc, and form a part of the risk assessment and abatement process.

Risk Assessment Example

Risk assessment guidelines can be found though Worksafe websites, and this is an example of a risk assessment for general Fab lab operations. Individual activities and equipment would have their own risk assessment done as a preliminary to the development of Safe Work Instructions and SOPs.

Hazard labels

If hazardous materials are decanted from their commercially supplied container (which will have appropriate labels attached), then you are required to label the new containers. This is a word document with commonly used hazard signs that can be reformatted for printing your own labels as required.

Safety Data Sheets

Also known as SDS or previously, MSDS.

You are required to have available copies of the SDS for every hazardous material present in your facility. These can be made available to staff electronically, or in hard copy, and must be no more than 5 years old. Manufacturers are required to make these available for download, and they can easily be found with a simple search.

Our FabLab has printed copies of the relevant SDS available in each work area for ready access (avoiding problems with access to staff networks).