Work, Health and Safety Management System Manual

Disclaimer: This document contains material to assist in addressing Work Health and Safety management obligations. Every effort has been made to ensure the accuracy of this information at the time of publication, it is provided as guidance only to current WHS legislation. This document contains material sourced from Safe Work Australia [1] and Work Safe QLD [2]. Any such material remains subject to copyright © to these governing bodies.

[1] https://www.safeworkaustralia.gov.au/copyright [2] https://www.worksafe.qld.gov.au/home/copyright

Introduction

This Work Health and Safety Management System (WHSMS) Manual is designed to assist in meeting Work Health and Safety (WHS) obligations under the current Work Health and Safety Act 2011 and current WHS Regulations 2011 and includes processes in place for management of health, safety and environment for Fabrication Lab workspaces located at The Edge State Library of Queensland. The WHSMS Manual will be available for inspection by all relevant persons, including visitors, direct relevant workers, contractors, Health and Safety Representatives (HSR), contractors, relevant workers of contractors and government appointed inspectors. Monitoring of the WHSMS Manual and updated as required and keep the most current copy at:

Hard Copy Location: The Edge Fabrication Lab, Clean Lab, Level 0, Staff office.

The WHSMS Manual will include essential information for people at the workspace to ensure health and safety as far as is reasonable. It will consist of roles and responsibilities of key personnel, Health and Safety Representative (HSR) and participation arrangements, guides for resolving issues, and processes in place for hazard identification, risk assessment and controls, managing incidents, emergency response and review/monitoring procedures.

Failure to comply with the requirements of the WHSMS Manual may lead to disciplinary action, which can include possible dismissal, loss of contract and legal action for severe breaches.

Note: For the purpose of this WHSMS, the term “workspace” includes any private, business or commercial premises/site, permanent or temporary, at any location, at which The Edge Fabrication Lab workers undertake related tasks/jobs, including the premises of the Person who Conducts a Business or Undertaking (PCBU).

Review Procedure

The Management will review the WHSMS Manual as required. The review schedule will be in response to organisational changes and relevant legislative amendments as they occur. Reviews will be undertaken in consultation with workers, HSR’s and other relevant parties. All relevant people will be made aware of changes made as a result of the review.

The WHSMS Manual will undertake review if:

- It is identified that there are changes in the workspace that affect the WHSMS;

- It is identified that the WHSMS is not effective;

- There are legislative changes that affect the WHSMS;

- There is a serious incident or dangerous occurrence or near miss.

The WHSMS Manual will be reviewed at least once (1) annually.

Document Control

The WHSMS Manual is a controlled document. All unauthorised copies either electronic or printed are considered uncontrolled copies. Copyholders and the version distributed to them will be recorded in the Distribution Record.

All versions of the WHSMS Manual will have a unique document number and version number, records of which kept in the Document Register, including the date of approval, and review date.

All versions of the WHSMS Manual are held as a record. In the event of a notifiable incident, the relevant WHSMS Manual and supporting documentation (initial and reviewed versions) will be held for a period of five years after the incident. During this period, the WHSMS Manual it will be accessible to all relevant persons and Government appointed officers as required.

Work Health and Safety Management System (WHSMS)

The State Library of Queensland recognises its moral and legal responsibility to provide a safe and healthy work environment for workers including contractors, volunteers, members and visitors to the space.

Objective: Our aim is to encourage a positive health and safety culture within the space. To ensure this occurs, work health and safety will be actively promoted throughout the organisation by the provision of information, training, instruction and supervision. The State Library will openly encourage all people to report hazards, including near misses, without fear of reprisal.

Scope: This applies to all people who are engaged to undertake tasks at The Edge Fabrication Lab workspaces/locations including workers, independent contractors and volunteers.

The State Library is committed to prevention of injury and ill health of its staff, contractors, volunteers, members and visitors within its working environment. It is to ensure that any work carried out within the scope of the business is conducted in compliance with the QLD Work Health and Safety Act 2011, QLD Work Health and Safety Regulation 2011 and complies with all applicable regulatory requirements.

Emphasis will be placed on effective management ensuring a systematic approach to the identification of risks using a hierarchy of controls and, the allocation of financial and physical resources to control these risks. In order to deliver these responsibilities, The State Library undertakes to:

- Maintain a safe and healthy space by providing plant, equipment and systems of work which reduces risks to people’s health and safety;

- Promote WHS awareness within the organisation and encourage workers to participate in the decision-making processes within the WHSMS;

- Ensure compliance with all relevant safety legislation, regulations, codes of practice and other requirements associated with our operations;

- Where any process or service is outsourced the State Library will determine criteria and methods of control to ensure conformity to our requirements and regulatory authorities.

- Arrange for the effective planning, organisation, control, monitoring and review of preventative and protective measures;

- Have in place a framework for setting and reviewing our WHS objectives and targets;

- Train, educate and inform our workers about WHS issues that may affect their work; and

- Commit to reporting WHS performance with measurable targets to ensure continued improvement.

This WHSMS is deemed appropriate for The Edge Fabrication Lab and includes a commitment to comply with the WHSMS and all applicable regulatory requirements.

Section 1 CONSULTATION, COOPERATION and COORDINATION

1.1 Consultation, Cooperation and Coordination

Objective: To establish formal consultation, cooperation and coordination methods, to allow workers and other duty holders, such as contractors and volunteers to address health and safety matters relevant to them.

Scope: This applies to all persons who conduct work for The Edge Fabrication Lab, irrespective of their individual employment arrangement. This covers all persons who are directed and/or engaged to undertake tasks at The Edge Fabrication Lab workspaces/locations including workers, independent contractors and volunteers. Also, visitors and any third parties that may be impacted by WHSMS at The Edge Fabrication Lab will be included in consultation and communication in respect of WHSMS matters as and when required, determined by the Workspace Manager/Supervisor/Health and Safety Representative.

The State Library will ensure formal Consultation, Cooperation and Coordination methods are established so workers and other duty holders, such as contractors and volunteers are aware of health and safety matters relevant to them. QLD WHS legislation requires a Person who Conducts a Business or Undertaking (PCBU) to consult with their workers and other relevant persons on matters that will or are likely to directly affect their health and safety. The State Library recognises the benefits that regular and effective consultation including, consultation, cooperation and coordination can produce and is committed to fulfilling this duty.

The State Library will follow AGREED consultative arrangements in line with WHS legislative requirements:

- Consult and work with SLQ health and safety committee;

- Elected a health and Safety Representative (HSR);

- Implement WHS as a standing agenda item at regular team meeting.

Further to this, consultation will take place in the following ways:

- Formal inductions;

- Training;

- Information on hazards and the existing WHSMS manual;

- Emergency response;

- Incident investigation and corrective actions;

- Results of WHSMS evaluations including audits, non-conformances;

- Review of WHSMS objectives;

- Safe work procedures;

- Risk assessments, risk controls and feedback regarding long-term controls;

- Safety Data Sheets (SDS), product safety sheets, operating manuals etc.;

- Reporting and keeping records in line with legislative requirements.

The State Library will modify the above information for languages other than English and those with learning disabilities as relevant/if needed.

The consultation will be timely and allow for relevant persons to contribute their views and feedback. Consider feedback on hazard identification, risk assessment and implementation of risk controls.

1.2 Consultation, Cooperation and Coordination Procedure

- Responsibilities:

At State library the management representative is responsible for ensuring that:

- There is an active consultation, cooperation and coordination procedure and associated mechanisms in place that meet legislative requirements;

- All workers are trained and familiar with, have access to and participate in the consultation, cooperation and coordination procedure and associated mechanisms while working at The Edge Fabrication Lab;

- All relevant workers and HSR are consulted in the preparation of Safe Operating Procedures (SOP);

- Others, who are impacted by WHSMS at The Edge Fabrication Lab, such as additional SLQ departments, contract workers, volunteers and visitors, are included in consultation as required;

- Review of the consultation, cooperation and coordination procedure as needed.

- Informing workers and others about the requirement to participate in activities, and follow, the consultation, cooperation and coordination procedure and associated mechanisms while working at The Edge Fabrication Lab;

- Ensuring there is adequate training for all people on how to consult and coordinate in the workspace;

- Conducting, and enabling, regular consultation with all workers and workgroups;

- Maintaining records relating to consultation.

The HSR/Safety Committee is responsible for:

- Maintaining and reviewing the consultation, cooperation and coordination procedure as required;

- Ensuring all workers have access to adequate consultation mechanisms and that they actively participate in consultation in the workspace;

- Informing and consulting with the Management Representative and CEO regarding consultation as necessary;

- Maintaining formal, approved consultation mechanisms and records required by legislation.

All workers and others are responsible for actively participating in consultation and for following reasonable directions in respect of WHSMS consultation procedures while working at The Edge Fabrication Lab.

- Procedure:

The State Library has established the following agreed consultative arrangements in line with WHS legislative requirements:

- Consult and work with SLQ health and Safety committee;

- Elected a Health and Safety Representative (HSR);

- Implement WHS as a standing agenda item at regular team meeting.

Consultation mechanisms at The Edge Fabrication Lab include the following:

- Formal induction training following the workspace induction procedure;

- Training as outlined in the training and competency assessment procedure and the workspace induction procedure;

- Information on hazards and the existing WHSMS Manual;

- Emergency response as described in the emergency management section of the WHSMS Manual;

- Incident investigation and corrective actions as detailed in the incident reporting procedure;

- Results of WHS evaluations including audits, non-conformances;

- Review of WHS objectives;

- Safe work procedures;

- Risk assessments, risk controls and feedback regarding long-term controls;

- SDS, product safety sheets, operating manuals etc.;

- Reporting and keeping records in line with legislative requirements.

In the first instance, workers who identify WHS issues in the workspace, or who wish to communicate with The Edge Fabrication Lab concerning WHS issues, should contact their supervisor or manager.

If it is not possible, or the worker feels uncomfortable to raise a particular WHS issue with their supervisor or the WHS manager, they should contact their HSR for assistance and consultation.

Workers who are HSR's are deemed to represent workers in particular work groups/departments and as such, will undertake regular, meaningful consultation with the workers in their work group. They will also respond to WHS issues raised with them by a worker or group of workers, by their duties as an HSR.

HSR's are then empowered to raise WHS issues formally at meetings with the supervisor or manager and with the Health and Safety Committee. They may in certain circumstances contact the relevant State authority for assistance and information.

The Health and Safety Committee will coordinate, manage, resolve and document any formally raised WHS issues, in consultation with the relevant workers and HSR's involved with the matter. They will then report and consult to the Management Representative and CEO regarding the nature and outcome of the issue.

The Management Representative will engage in the consultation procedure about WHS issues identified and raised at The Edge Fabrication Lab by the HSR or Health and Safety Committee.

The State Library will foster a culture of open communication and discussions relating to health and safety and furthermore, ensure that workers' interests are efficiently represented through formalised consultative arrangements.

The consultation will take place directly with workers, or where elected the HSR, to identify and assess hazards, before and during the implementation of risk controls, and whenever there are changes or new information. The consultation will be timely ensuring views are heard, and workers/duty holders can contribute to decision making as appropriate. In the event of a dispute about WHS issues, the issue resolution procedure will be followed.

The determination of the SLQ Health and Safety Committee is active to ensure all workers have ready access to an HSR (or Deputy HSR as agreed). The composition and location of work groups are as follows.

Health and Safety Representative

HSR’s and Deputy HSR’s will be elected via the following agreed procedures to represent the work groups for this workspace. The term of office of HSR’s/Deputy HSR’s may be up to 3 years and is open to re-election.

HSR Election Procedure

Workers may elect an HSR after agreement on work groups has been reached. The State library will provide any resources, facilities and assistance reasonably necessary to enable the elections to be conducted.

Undertake the following procedure:

- Call for nominees by inviting all work groups to participate:

- All workers are eligible to nominate and be elected as an HSR or deputy HSR for their defined work group;

- Workers will inform the Management Representative of the election date;

- Conduct election (either informally by a show of hands or a more formal process such as secret ballot):

- By the agreed method;

- Each member of the workgroup may only vote once in the election;

- Give all members of the workgroup the opportunity to vote;

- Advise workgroup members of the election results;

- Advise the Health and Safety Committee Chair of the election results.

Deputy HSR’s

In the HSR’s absence, a deputy HSR effectively becomes the HSR with the same powers of that role. Elect deputy HSRs in the same way as HSRs.

1.3 Safety Meetings

WHS meetings will be held Quarterly with the HSR and Management representative present. Any additional team members that are required to attend will be advised before the meeting date. The meeting is an opportunity to discuss improvement of operational practices and to develop safety plans.

Should the need arise for more frequent WHS meetings or an emergency debrief is required as a result of an incident, all relevant workers will be informed.

Safety Meeting Aims:

| * Making relevant workers’ more aware of safety at work; * Bringing together management and relevant workers; * Stimulating an interest in safety; * Educating relevant workers’ in safe working practices; * Accessing a more extensive range of viewpoints; * Developing preventive measures not reactive action; * Sharing incidents and workspace procedural changes. |

Records will be maintained of the topics covered; outcomes recorded, in the Safety Meeting/Safety Talk Record.

1.4 Issue Resolution

Objective: To ensure that all WHS issues arising in the workspace are resolved in an efficient, timely and suitable manner to enable maintenance of a safe and healthy work environment at The Edge Fabrication Lab.

Action: This will provide guidelines for a consultative, systematic and fair approach to resolving work health, safety or welfare issues that may arise. The Edge Fabrication Lab will adhere to the guidelines and requirements of the current QLD WHS Legislation and follows a process of natural justice to resolve any WHS issues raised in the workspace.

In attempting to resolve any WHS issue, The State Library will have regard to relevant matters, including, but not limited to:

- The degree and immediacy of the risk to workers or other people affected by the WHS issue;

- The number and location of workers and other people affected by the WHS issue;

- Corrective measures (temporary and permanent) that must be implemented to resolve the issue, using appropriate mechanisms to eliminate and control risks;

- Who will be responsible for implementing the resolution measures;

- Consultation between all parties involved and affected by the WHS issue.

Workers will not be penalised, in any way, due to a safety issue being raised and actioned at The Edge Fabrication Lab.

1.5 Issue Resolution Procedure

This procedure will provide a practical framework to enable the resolution of any WHS issue that may arise at The Edge Fabrication Lab.

- Responsibilities:

At the State library the Management Representative is responsible for ensuring that:

- There is an effective Issue Resolution Procedure and associated mechanisms in place that meet legislative requirements;

- All The Edge Fabrication Lab workers, when required, are trained and familiar with, have access to and participate in the Issue Resolution Procedure and related devices;

- Conduct a review of the Issue Resolution Procedure as required.

- Informing workers and others about the requirement to participate, and follow, the Issue Resolution Procedure and associated mechanisms while working at The Edge Fabrication Lab;

- Ensuring adequate training for all relevant workers on how to track and action the Issue Resolution Procedure in the workspace;

- Conducting, and enabling, issue resolution when required with all workers and workgroups;

- Maintaining records required by legislation relating to issue resolution.

The HSR/Health and Safety Committee is responsible for:

- Maintaining and reviewing the Issue Resolution Procedure as required;

- Ensuring all workers have access to adequate issue resolution information and mechanisms and that they actively participate in issue resolution when needed in the workspace;

- Informing and consulting with the Management Representative/CEO regarding issue resolution as necessary;

- Maintaining formal, approved issue resolution mechanisms and records required by legislation;

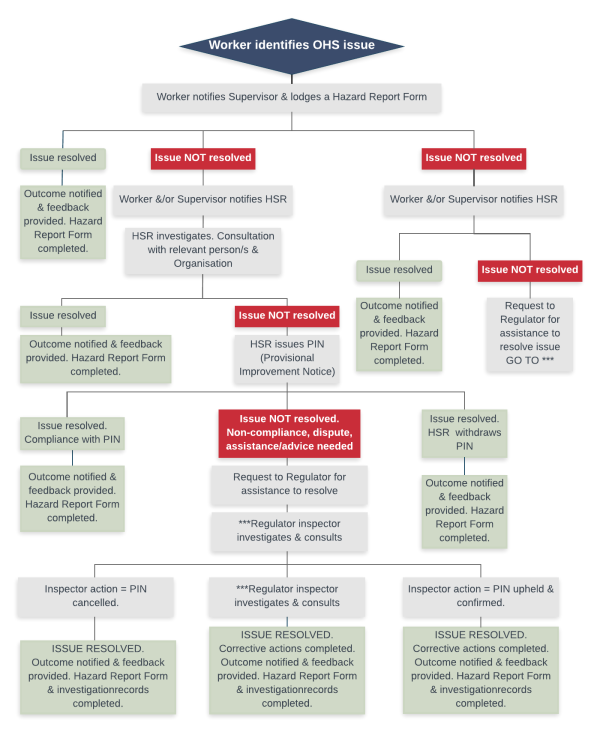

- Seeking assistance from the regulator when needed, as per the Issue Resolution Procedure Flow Chart (Figure1. page 12) and the requirements of current legislation.

All workers are responsible for actively participating in and following reasonable directions in respect of issue resolution while working at The Edge Fabrication Lab when required.

Figure1. Issue Resolution Procedure Flow Chart

Informal Issue Resolution Procedure: A workers who wishes to raise a WHS hazard/concern should first discuss the issue directly with their supervisor or manager. The supervisor/manager will:

- Consider and investigate the matter, including contacting other relevant workers at The Edge Fabrication Lab who may be able to assist in resolving the WHS issue;

- If possible, implement or arrange to implement, actions to address the hazard/issue, as soon as possible;

- Consult with and inform the worker who raised the issue of the outcome of the investigation, and all corrective actions;

- Ensure to complete and retain a Hazard Report Form as a record of the issue, the result and resolution;

- Monitor and review the issue at an appropriate and agreed time to ensure there is no repeat of the issue.

If the WHS issue is resolved satisfactorily at this stage, then there is no need for further action.

If the WHS issue is NOT resolved, at this stage, the problem will progress to the Formal Issue Resolution Procedure. Refer to Figure 1. Issue Resolution Procedure - Flow Chart.

In the event of a severe immediate risk to workers: In the situation when a definite and direct safety hazard is perceived, and the issue is considered critical and urgent, the worker or HSR will inform the relevant supervisor, who will call an immediate halt to work to investigate the matter.

If the Management Representative fails to agree about the degree of risk present or is not available, an HSR or a worker from that workgroup will direct affected workers (and any others who may be affected) to withdraw from the alleged hazard. They will then inform the appropriate manager of the actions taken pending a full investigation.

Work will not resume until the hazard has been controlled and no longer presents an unacceptable risk to the safety and health of workers and others.

Section 2 RISK MANAGEMENT

2.1 Risk Management

Objective: To embed principles of effective risk management into existing practices at all levels of the organisation.

Scope: This applies to all workers of the State Library, irrespective of their employment arrangement. This covers all people engaged to undertake tasks at The Edge Fabrication Lab workspaces/locations including independent contractors and volunteers.

Action: Risk is inherent in all The Edge Fabrication Lab functions. All The Edge Fabrication Lab personnel are responsible for managing the risks that relate to their particular area of work.

The following structure for risk management will apply.

- Where specific regulations require certain controls:

- The Edge Fabrication Lab will ensure compliance with those matters, in consultation with relevant persons (including Duty Holders/Contractors);

- Hazard Identification:

- Identify reasonably foreseeable hazards that may pose risks to health and safety;

- Evaluate risks where required:

- Compare estimated levels of risk against pre-established criteria (including a risk matrix) and consider the balance between potential benefits and adverse outcomes;

- Manage risk:

- Elimination of risk being the first option investigated and instigated for a control action;

- Where the risk cannot be eliminated, minimise the risk so far as is reasonably practicable;

- Implement risk controls:

- Secondary to elimination, selection of controls will follow a hierarchy:

- Substitution with less hazardous options;

- Isolate people from the hazards;

- Use of engineering controls;

- Where risk remains:

- Implement administrative controls;

- Where risk remains:

- Use of PPE;

- Use any one or a combination of these controls as appropriate;

- All controls must be fit for purpose, suitable for the nature and duration of task and installed set-up, and used correctly;

- Review risk controls whenever:

- Control is no longer effective;

- Before any change likely to introduce new or different hazards that current controls will not adequately address;

- A further hazard or risk is identified;

- Results of consultation indicate a review is needed where requested by workers or Health and Safety Representative.

2.2 Risk Management Procedure

This procedure will assist in the early detection of hazards, the assessment of risks and the implementation of control mechanisms in line with the needs of the workspace.

- Responsibilities:

At The Edge Fabrication Lab the Management Representative is responsible for ensuring that:

- There is an effective Risk Management Procedure and associated mechanisms in place and that they meet QLD WHS and Worker’s Compensation legislative requirements;

- All workers are trained and familiar with, have access to, and participate in risk management policies, procedures and activities while working at The Edge Fabrication Lab;

- Others who are impacted by WHS at The Edge Fabrication Lab, such as additional SLQ departments, volunteers and visitors, are included in risk management strategies as required;

- Conduct a review of the Risk Management Procedure as necessary.

- Informing workers and others about the requirement to actively participate in risk management strategies and to follow risk management policies and procedures while working at The Edge Fabrication Lab;

- Ensuring adequate training for all people in how to participate in risk management activities in the workspace;

- Maintaining records required by current QLD WHS Legislation relating to risk management.

All workers are responsible for working safely and for following reasonable directions in respect of the WHS Risk Management Procedure and associated mechanisms while working at The Edge Fabrication Lab.

- Procedure:

The State Library has implemented a step-by-step mechanism to provide the required system and tools to ensure effective risk management in the workspace. They are as follows:

- Communication – the Consultation, Cooperation and Coordination and associated procedure are in place to enable risk management to be implemented systematically and efficiently, involving all people impacted by WHS at The Edge Fabrication Lab. Effective consultation and planning is essential during every phase of the Risk Management Procedure and associated activities;

- Hazards are identified and reported via the following:

- Consultation – WHS Meetings, HSR, briefings, direct discussions etc.;

- Workspace inspections;

- Audits – internal and external (photos, observations, checklists, reports);

- Reporting – Incident Forms, Hazard Report Form, Hazardous Chemicals/Dangerous Goods Register etc.;

- Research – gather and interpret information from State and Local Authorities, manufacturers, suppliers, industry groups, other PCBU and workers;

- Risk assessment – conduct workspace-specific, task-specific, chemical and plant risk assessments and environmental impact risk assessments as required by suitably trained and experienced workers;

- A Risk Assessment Matrix (figure 2) which accompanies each risk assessment form is used to assist in determining risk levels;

- Actions prioritised – assess risk levels then a list of action priorities is determined;

- Risk control – identified hazards are systematically eliminated or reduced by implementing practical control measures. Use the Hierarchy of Controls (Figure 3);

- Monitor and review – regular checks are carried out to ensure the implementation of suitable control measures, that they continue to be adequate, and that no new hazards have been introduced into the workspace either by implemented control actions or by changes to the workspace;

- Documentation – all risk management activities conducted and the outcome of those activities, in particular, those outlined in this procedure, are fully documented and records maintained.

It is essential that workers continue to look for hazards in the workspace at all times, not just during risk management activities. All hazards that cannot be eliminated immediately must be reported to the Management Representative using hazard-reporting mechanisms. Consider the potential for the introduction of new hazards in the workspace when planning or changing work tasks, equipment etc. in the workspace.

Environmental risk management, including the potential for chemical spillage, is included in all relevant risk management policies and procedures within The Edge Fabrication Lab.

Where identified hazards and risks are well known and subjected to accepted risk control measures, no further risk assessment will be required, and risk controls can be implemented. These controls, however, will be monitored and reviewed accordingly. For all other identified hazards, a risk assessment or job safety analysis must be undertaken to determine how likely to the hazard is to harm people, and how severe the harm could be. The process used to conduct a risk assessment is outlined below in Figure 2 Risk Assessment Matrix.

Risk Assessment Matrix

| Stage 1: Determine Likelihood: What is the possibility that the effect will occur? | ||

|---|---|---|

| Likelihood | Criteria | Description |

| Almost certain | Expected in most circumstances. | The effect is a typical result. |

| Likely | Will probably occur in most circumstances. | The effect is known to have occurred previously. |

| Possible | Might occur at some time. | The effect could occur or, examples of it happening. |

| Unlikely | Could occur at some time. | The effect is not likely to occur or, no examples of it happening before. |

| Rare | May occur only in exceptional circumstances. | The effect is practically impossible. |

| Stage 2: Determine Consequence: What will be the expected effect? | |

|---|---|

| Level of Effect: | E.G. of each level: |

| Insignificant/Acceptable | No effect or treatment required - or so minor that effect is acceptable. |

| Minor | Minor effect or injury - On-site first aid treatment only. |

| Moderate | Serious injuries - Injury requiring medical treatment. |

| Major | Extensive injury - Requires specialist medical treatment or hospitalisation. |

| Catastrophic | Permanent total disability injury, multiple injuries and death/es. Substantial environmental harm, prosecution/imprisonment. |

| Stage 3: Determine the risk score: | |||||

|---|---|---|---|---|---|

| Consequence | |||||

| Likelihood | Insignificant | Minor | Moderate | Major | Catastrophic |

| Almost certain | 3 High | 3 High | 4 Extreme | 4 Extreme | 4 Extreme |

| Likely | 2 Mod. | 3 High | 3 High | 4 Extreme | 4 Extreme |

| Possible | 1 Low | 2 Mod. | 3 High | 4 Extreme | 4 Extreme |

| Unlikely | 1 Low | 1 Low | 2 Mod. | 3 High | 4 Extreme |

| Rare | 1 Low | 1 Low | 2 Mod. | 3 High | 3 High |

| Stage 4: Record risk score on the worksheet: (Note – Risk scores have no absolute value and should only be used for comparison and to engender discussion.) | |

|---|---|

| Score | Action |

| 4E: Extreme | DO NOT PROCEED. Requires immediate attention. Introduce further high-level controls to lower the risk level. Re-assess before proceeding. |

| 3H: High | Review before commencing work. Introduce new controls and/or maintain high-level controls to lower the risk level. Monitor frequently to ensure control measures are working. |

| 2M: Mod. | Maintain control measures. Proceed with work. Monitor and review regularly, and if any equipment/people/materials/work processes or procedures change. |

| 1L: Low | Record and monitor. Proceed with work. Review regularly, and if any equipment/people/materials/work processes or procedures change. |

Figure 2. Risk Assessment Matrix

Work health and safety laws require selecting risk controls following a “Hierarchy of Control”. As far as reasonably practical, risk must be eliminated. Where this is not possible, risk can be reduced using substitution, isolation and engineering controls. For remaining risk, use administrative controls and PPE. Risk controls must be reviewed and monitored to ensure they remain effective.

All controls will be reviewed and monitored:

| * When/if incident/near miss occurs; * As per legislative requirements; | * As requested by relevant persons (such as HSR); * Other times necessary to ensure effectiveness. |

It is essential to consult with relevant workers during the selection of controls and remember that any changes to the task (including introducing new equipment and ways of doing things) can result in further risks. Provide sufficient training, information, instruction and supervision where required.

| Elimination - Risk will be eliminated where possible. Examples: | ||

|---|---|---|

| No Hazardous Manual Handling tasks | No hot work | Pre-cut and pre-made materials / parts |

| Substitution Isolation Engineering - Where risk remains, one/combination of controls will be used. Examples: | ||

| * Store and stack items to minimise risk from hazardous manual handling * Restrict weight and size of items to be handled manually * Industrial racking systems * Use mechanical lifting and materials handling devices | * Welding bay * Welding curtains * Gas bottle trolleys * Restricted zones in workshop * No chemicals or flammable materials in or near hot work area | * Guards on machines/tools to prevent access to blades, pinch spots, moving parts * E- stops, Lock Out and Tag * Operator bays/restricted zones * Sensor curtains / alarms |

| Administrative - Where risk remains, administrative controls will be used. Examples: | ||

| * Risk Assessment * Hazardous Manual Task training | * Operational manuals * Hot Work Permits * Signage | * Training and education * Machine/vehicle maintenance programs * Pre-start checklists |

| Personal Protective Equipment (PPE) - Where risk still remains, it will be reduced as far as reasonably practicable with use of PPE. Examples | ||

| * High visibility vest * Gloves * Overalls | * Full face shield * Hearing protection * Welders Gloves | * Welding apron * Safety goggles/glasses * Work boots |

Figure 3. Hierarchy of Controls

2.3 Objectives and Targets

Objective: To provide all State Library workers and others with achievable, measurable and accountable outcomes.

Scope: These objectives and targets apply at all The Edge Fabrication Lab workspaces and will fall under the responsibility of nominated managers/supervisors.

The State Library is dedicated to providing a workspace that is free of injury and illness and promotes a culture of safety first. The Edge Fabrication Lab is committed to making WHS an integral part of decision making in all operations.

The State Library will measure objectives based on the following:

- Having a WHSMS that incorporates both WHS outcomes measurements and positive performance of risk management processes;

- The provision of physical and human resources to ensure that the objectives and targets of all WHS policies and procedures embedded within the WHSMS Manual will be achieved;

- Meet WHS Legislative requirements;

- An open and transparent consultation that encourages and enables continual improvement of internal systems and outcomes.

Targets will include:

- Reduction in Lost Time Injury (LTI) rate annually; (Human Resources)

- Reduction in LTI – average days lost; (Human Resources)

- Complete inspections/audits within specified timeframes; (WHS Committee)

- Corrective actions completed within specified timeframes; (WHS Committee/HSR)

- Undertake Emergency Response Plan practices within specified timeframes; (WHSA)

- Review of consultative arrangements. (WHS Committee)

Performance targets will be set specific to the workspace and incorporated into position descriptions and performance evaluation for individuals and organisation.

2.4 Objectives and Targets Procedure

WHS performance in the workspace will be measured and analysed and responsibilities allocated to individuals within the company to assist in meeting WHS targets and to encourage continual improvement.

- Responsibilities:

At The Edge Fabrication Lab the Management Representative is responsible for ensuring that they:

- Develop and implement a WHSMS Manual;

- Identify and assess the training needs of workers;

- Establish contractor management procedures;

- Establish effective consultation mechanisms with all relevant persons.

- Assist with the implementation and day to day operation of the WHSMS Manual;

- Provide and organise WHSMS training for workers as required;

- Respond quickly to hazards reports and action corrective actions;

- Respond to incidents and ensure procedures are followed and undertake investigations as appropriate;

- Ensure implementation, monitoring and reviews of contractor management procedures;

- Practically implement consultation mechanisms with workers, contractors, volunteers and other departments.

Workers are responsible to:

- Know and follow the WHSMS Manual and WHSMS plans at The Edge Fabrication Lab;

- Participate in WHS training and induction as and when required;

- Participate in return to work plans;

- Cooperate with incident investigations and hazard corrective actions;

- Actively participate in consultation in the workspace.

- Procedure

Objectives:

- All workers are informed and trained in their WHS roles and responsibilities;

- All workers conduct themselves in a safe and responsible manner;

- Identify and meet WHS training needs;

- Minimise incident frequency and severity;

- Contractor management systems are in place and working effectively;

- WHSMS is in place and implemented effectively by all workers and management;

- Undertake workspace inspections and audits;

- Hazards are identified, and action is taken to eliminate or reduce and control related risk;

- To fully document all WHSMS activities, training, incidents, systems and outcomes in the workspace.

Targets:

- All workers know and adhere to their WHS roles and responsibilities;

- All workers are familiar with and follow the WHSMS;

- All workers are trained and deemed competent in accordance with the requirements of their job and current WHS Legislation;

- Zero incidents and injuries;

- Contractors produce evidence of insurances, SOP and demonstrate knowledge and competency in safe work practices and WHS systems;

- The WHSMS is fully implemented and operating effectively at The Edge Fabrication Lab;

- Workspace inspections and audits are conducted at least annually and more frequently as required;

- Documented records are kept of all WHS matters, incidents, training, inspections, and audits as required by current WHS Legislation.

Roles, Responsibilities and Accountabilities

Objective: Everyone in the workspace understands the need for health and safety, what their role is in making the workspace safer, and how they can fulfil their responsibilities and duties.

Scope: This applies to all workers, contractors and volunteers of The Edge Fabrication Lab.

Successfully managing health and safety in the workspace and environmental protection relies on commitment, consultation and co-operation.

The Edge Fabrication Lab allocates the following roles and responsibilities:

State Librarian/CEO (Officer):

- Approval of WHSMS documentation;

- Communication of WHSMS policies and objectives;

- WHSMS leadership;

- Allocating sufficient WHSMS resources;

- Reviewing WHS performance;

- Providing direction for increasing WHS performance;

- Establishing and promoting a WHS culture;

- Legal obligations to provide and maintain a safe workspace.

Applied Creativity Lead (Management):

| * Integration of WHS into all decision making; * Consult with workers and other duty holders/contractors; * Plan, develop, implement, monitor and review WHSMS policies, procedures and plans; * Control risks; * Support WHS committees; * Provide WHS communication; * Discuss WHS at relevant meetings; * Identify WHS training needs and enable training as required; * Reporting and recording; * Liaise with relevant regulatory authorities; * Legal obligations to provide and maintain a safe workspace. |

WHS Committees:

| * Develop, monitor and review WHSMS policies and procedures; * Monitor and report on WHS performance; * Monitor changes in legislation; * Review corrective actions; * Provide WHS information to workers. |

All workers, contractors and volunteers:

- Comply with WHS policies, procedures and plans;

- Work in a manner that is safe and does not create risks for themselves or others;

- Report and assist in rectifying hazards;

- Participate in consultative arrangements;

- Legal obligations to not endanger others by their acts or omissions.

| Roles, Responsibilities and Accountabilities Procedure | ||

| State Librarian/CEO | > | * Provision and maintenance of a work environment that is safe and without risks as far as is reasonably practicable; * Approve WHSMS; * Accountable for breaches of current WHS Legislation. |

| v | ||

| Applied Creativity Management | > | * Provision and maintenance of a work environment that is safe and without risks as far as is reasonably practicable; * Oversee WHSMS and consult with relevant persons; * Accountable for breaches of current WHS Legislation; * Integration of health and safety into all aspects of decision-making and operations; * Meeting WHS targets and objectives; * Monitoring, assessing and reviewing work health and safety. * Development and implementation of WHSMS, Monitoring, assessing and reviewing work health and safety targets and objectives; * Training and consultation; * Supporting and assisting workers with post-injury management. |

| v | ||

| WHSA SLQ WHS Committee | > | * Monitoring, assessing and reviewing WHSMS, SOP and WHS targets and objectives. * Meet as per agreed “Charter” to discuss WHS matters relating to The Edge Fabrication Lab including incidents, corrective actions and areas for improvement/target areas; |

| v | ||

| The Edge Fabrication Lab Workers Contractors Volunteers | > | * Take reasonable care of themselves and others at in the workspace; * Cooperate with WHS policies and procedures and relevant legislation/guidance; * Participation in consultative arrangements regarding WHS matters; * Assisting management to meet WHS targets and objectives. |

2.7 Environmental Management

Objective: To actively work towards elimination and reduction of adverse effects to the environment by incorporating environmental impacts into all levels of the organisation and utilising best practice techniques wherever possible. To work with workers, visitors and business partners to achieve compatibility between economic development and the maintenance of the environment to minimise harm.

The State Library recognises its moral and legal responsibility to minimise damage to the environment caused by work activities and is committed to conducting our business in an environmentally aware and responsible manner.

This commitment extends to ensuring that operations do not unnecessarily endanger flora, fauna, sensitive areas, workspaces of heritage importance or present concerns to members of the public and community.

The Edge Fabrication Lab will endeavour to minimise the impact of the following:

- Atmospheric emissions;

- Workspace contamination and spills;

- Noise emission;

- Damage to flora and fauna;

- Damage to, or interference with workspaces, areas or structures of indigenous or non-indigenous cultural heritage;

- Storm water management;

- Unnecessary energy consumption.

To fulfil this commitment, the State Library, will observe all environmental laws and promote environmental awareness among all workers to increase understanding of environmental matters.

The State Library will actively take part in the following:

- Assess eco-footprint to identify environmental impacts and move towards more sustainable practices;

- Identify waste streams and options for effective waste management;

- Improve purchasing (buy recycled materials, reduce waste, use less harmful/volatile chemicals and energy efficient equipment/appliances);

- Monitor energy consumption and promote equipment/appliance shut down during non-operational periods.

- Improve storage (minimise quantity, waste and spills, reduce odours by keeping containers closed);

- Conserve water (install water-saving accessories, repair leaks);

- Preserve waterways (clearly mark and protect stormwater drains);

- Emergency planning and spill response;

- Seek appropriate licenses/permits from State Environmental Protection Agencies and other relevant authorities;

- Notify relevant authority in the event of a significant environmental impact.

Section 3 MONITORING and REVIEWING

3.1 Legislative Change

Objective: Maintain awareness of legislative change.

Scope: This applies to all workers of the State Library charged with the responsibility to identify, monitor and action compliance as per legislation relevant to work health and safety of workers.

The State Library is committed to providing a safe and healthy workspace for workers, contractors and visitors and embraces opportunities to improve knowledge about new legislation and best practice solutions.

The State Library will proactively seek out advice, education and industry knowledge to foster continual improvement in WHS systems and updates of relevant legislation.

The State Library will endeavour to manage legislative change by:

- Assigning responsibilities for researching legislative variations with State and Federal Authorities;

- Participating in learning opportunities such as information sessions provided by industry stakeholder groups, unions, and relevant authorities;

- Seeking advice from suitably qualified people where required (such as work consultants);

- Attending conferences, trade shows etc. where possible;

- Ensuring refresher training is undertaken where required;

- Liaising with local authorities as needed.

3.2 Legislative Change Procedure

- Procedure:

The State Library has put in place mechanisms to manage legislative change by delegating the Work, Health and Safety Advisor WHSA to:

- Regularly reviewing WHS policies, procedures, systems and processes to ensure they are current and in line with relevant legislation;

- Reviewing WHSMS policies, procedures, systems and processes to maintain currency;

- Notifying, all relevant persons on the changes;

- Maintaining documented records of modifications to policies, procedures, systems and methods due to legislative changes via the document control system. Seeking advice from suitably qualified persons where required (such as WHS consultants) to assist with management of legislative changes;

- Ensuring workers can access relevant WHS information either in electronic form or hard copies as required;

- Liaising with local authorities as required.

3.3 Management Review

Objective: To identify areas for improvement in the management of the WHSMS.

Scope: This applies to all the State Library workers who sit on a WHS Committee, are an HSR or are a relevant managers/supervisor responsible for planning, development, use, and maintenance of the WHSMS.

The State Library recognises the importance of reviewing the adequacy and effectiveness of the WHSMS to identify opportunities for improvement.

Management meetings will be held at regular intervals and will include the following agenda items:

| * Review of internal and external audit results, inspection and other compliance plans; * Evaluation of legal compliance issues; * Results of participation and consultation from all levels - management, workers and contractors; * Performance evaluation of the WHSMS Manual and objectives; * Status of incident reports, investigations, corrective and preventive actions; * Communication from interested parties, complaints - take action status and suggestions; * Management of change; * Corrective actions, accountability and timeframes; * Follow-up action on previous management reviews. |

Determine meeting intervals/timeframes on a risk basis. Meeting minutes will be recorded, and results of these will be provided to Senior Management/Directors/Board Members.

3.4 Management Review Procedure

This procedure is accessible to all State Library workers, and all workers can input into the WHS management review process via management or elected HSR.

WHS Committee are held at regular intervals and include the following management review agenda items:

- Legislative requirements - including incident notification, hazardous work, licensing, certification and audits;

- Review of internal and external audit results, inspection and other compliance plans;

- Evaluation of legal compliance issues;

- Results of participation and consultation from all levels - management, workers and contractors;

- Performance evaluation of the WHSMS and objectives;

- Status of incident reports, investigations, corrective and preventive actions;

- Hazard reporting - corrective actions, accountability and timeframes;

- Recommendations for continual improvement;

- Communication between workers and other relevant parties, complaints - take action status and suggestions;

- Planned changes to the WHS (documents, processes, training etc.) that affect workers;

- Management of legislative change;

3.5 Compliance Evaluation

Objective: To establish an annual audit plan to identify any areas for improvement.

Scope: This applies to all State Library workers.

The Management Representative will evaluate performance and compliance with the current WHS Legislation and the worker's compensation provisions to create benchmarks for continual improvement of workspace safety.

The State Library is committed to the continual development, improvement and implementation of its work health and safety management systems.

At the State Library, compliance with legislation and this WHSMS is evaluated using several strategies including, but not limited to:

- Review of internal and external audit results, inspection and other compliance plans;

- Evaluation of legal compliance issues;

- Results of consultation from all levels - management, workers and contractors;

- Performance evaluation of the WHSMS Manual and work, health and safety objectives;

- Status of incident reports, investigations, corrective and preventive actions;

- Communication from interested parties, complaints - take action status and suggestions;

- Corrective actions, accountability and timeframes;

- Follow-up on previous compliance reviews.

3.6 Compliance Evaluation Procedure

The State Library will implement the following:

- In-house inspections as required:

- Routine maintenance plans;

- Internal audits;

- External audits as required;

- Health surveillance monitoring where needed;

- Resourcing for inspections by regulatory bodies.

Undertake audits to evaluate compliance in line with:

- Legal obligations;

- Current WHSM Act and current WHS Regulations;

- The Edge Fabrication Lab WHSMS policies and procedures;

- AS/NZS 4801: 2001 Occupational Health and Safety Management Systems.

Reports detailing compliance evaluations, including audit and workspace inspection results will be recorded and results provided to SLQ WHS Committee or State Librarian/CEO at regular intervals.

Results of any audits, inspections and any corrective actions that indicate workers and relevant contractors may be at immediate at risk of harm must be actioned immediately.

3.7 Internal Audits

Objective: To define the process for undertaking internal audits of the defined WHSMS. This process will define the responsibilities for planning and conducting audits, reporting the results of audits, and retention of audit records.

The State Library is committed to assessing compliance with the WHSMS. By doing so we are ensuring that the system itself is effectively implemented and maintained. In order to assess compliance, regular internal audits will be undertaken.

Audit plans identifying criteria, scope, frequency, and methods will be developed and administered by the WHSA (or delegate). Audits will be scheduled, organised, performed and recorded in accordance with detailed procedures and work instructions. Suitably competent persons who are not accountable for WHS outcomes in the area being audited will perform audits.

All audit findings and results will be maintained and where corrective actions are identified, a report created accordingly, and management responsible for the non-conforming result ensure the necessary correction actions are taken without undue delay. All follow-up actions will be verified and signed off as complete by the WHS Manager (or delegate).

- Audit Procedure

Management Representative is required to:

- Implement an Audit Schedule to determine whether the WHSMS conforms to the documented policies and procedures;

- Allocate sufficient resources to ensure the WHSMS is properly effected and maintained;

- Provide audit findings to SLQ WHS Committee, WHSA, State librarian/CEO;

- Conduct all audits in a professional manner.

All Workers are required to:

- Participate and assist in internal audits as required;

- Bring it to the attention of their supervisor/manager immediately any issue that may affect a current audit.

The Management Representative will:

- Develop an internal audit plan;

- Ensure an internal audit of the WHSMS is undertaken annually (At minimum);

- Select an audit team (ensuring the auditor team has appropriate audit training);

- Appoint an leader auditor (if not themselves);

- Establish and implement an Internal Audit Plan; (considering breadth and depth of audit);

- Communicate the audit schedule to the organisation;

Audit Team Selection:

One or more auditors may comprise an audit team:

- If the team is made up of more than one auditor, a Lead Auditor will be nominated;

- The Lead Auditor will be responsible for coordinating the audit process, and preparation of the final audit report;

- The Lead Auditor will ensure that the team understands the scope of the audit;

- The Lead Auditor will ensure that relevant organisational WHSMS policies, procedures and other documents are made available before the audit commences (ensuring a reasonable notification time for audited departments prior to the audit).

- Audit Plan

The Lead Auditor is responsible for ensuring the preparation of a written audit plan. See Fabrication Lab Inspection Checklist.

The audit plan will consider:

- Relevant system documents and records;

- Internal audit criteria and components

Conducting the Audit:

- A pre-audit meeting is held with appropriate personnel to confer on the scope, plan and timing for the audit;

- The Lead Auditor may modify the audit scope and plan if necessary;

- All audit findings must be documented;

- Corrective actions from previous audits must be considered and documented;

- A post-audit meeting will be held to present preliminary audit findings, clarify any misinterpretations, and summarise the audit outcomes.

Reporting audit outcomes:

- The Lead Auditor will prepare an audit report;

- The audit report will state the scope of the audit, identify the audit team, define the evidence used, and summarise the results of the audit;

- Audit findings indicating that corrective actions are required must be entered into the Corrective / Preventative Action Register;

- The Management Representative is responsible for distributing the audit results to SLQ Work, Health and Safety Advisors WHSA, WHS Committee, State Librarian/CEO

The Management is responsible to ensure audit reports are tabled for review at next Management Review (see next section).

Audit follow-up:

- Non-conformances identified as a result of the audit will be listed in the Corrective / Preventative Action Register;

- The Management Representative will be responsible for the completion and effectiveness of corrective actions.

Record keeping:

- All Internal Audit Reports will be retained for at least two years from the date of the Audit;

- The WHS System Audit manager is responsible for assigning audit records to the WHS System Manager for storage (including any records relating to the training of auditors).

Note: Should any evidence collected during the internal audit suggest an extreme risk exists, this information must be communicated directly to Management Representative/CEO immediately. Work tasks involving the identified extreme risk must stop and implement effective control measures.

3.8 Document and Record Keeping

Objective: To define, document and communicate the documents and record keeping and procedures for all elements of The Edge Fabrication Lab WHSMS.

Scope: This covers all State Library workers who obtain, create, use, edit, review and store documents and records.

To ensure effective operation of the WHSMS, the State Library will ensure that documents and records are easily located, relevant and kept up-to-date. At The Edge Fabrication Lab, the control of document information ensures that:

- Documented information is readily available to workers and managers and that it is suitable for use; and

- Documented information is protected from loss of confidentiality about our processes, improper use or loss of document integrity.

In the control of documented information including records management, the following actions are taken to ensure documents, content and records are:

- Able to be distributed, accessed, retrieved and used in an appropriate, effective and efficient manner;

- Stored and preserved including legibility for prescribed times as per legislative or regulatory requirements;

- Version controlled and changes are documented and communicated;

- Retained and disposed of according to legislative or regulatory requirements;

- All electronic forms will be maintained and backed up as per document keeping procedure;

- All hardcopy records will be protected from damage by storage in suitable locations.

Records subjected to regulated timeframes must be kept for the required period. All other records will be kept for a period in line with the State Library record disposal schedule.

Where documented information is of external origin i.e. outside of The Edge Fabrication Lab and is necessary for the planning and operation of our processes then, the documentation will be identified. Once identified, the document will be controlled in the same manner as internally generated documented information.

Documented information retained as evidence of conformity in the form of records will be protected and stored for the length of time required by regulatory requirements. The WHS records kept by the State Library are detailed in the WHSMS Document Register.

The types of documents that can be controlled documented information include (but are not limited to):

| * HTML and Java scripted Web Pages; * WHSMS Manual; * Procedures; | * Work Instructions; * Forms; * Company templates. |

Records such as:

| * Corrective Actions; * Management Reviews; | * Visitor Complaints; * Calibration Results. |

All printed documents are considered uncontrolled.

The documents are to be approved by the Management Representative and only nominated people shall have the authority to create and modify documents. Control external documents such as law guides, standards and legislation through subscription to online databases, which maintain up-to-date versions of all materials.

Control health and safety records and worker's compensation records in accordance legislative requirements. Nominated persons shall have responsibility for holding, storing, retaining and disposition of WHS related records.

The State Library will keep records in line with specific legislative requirements for health monitoring data, injury records, risk assessments, SOP, notifiable incidents, and other specified matters. Records will be kept for the required timeframe and will be accessible for review by regulatory bodies, WHSA and HSR as appropriate.

3.9 Document and Record Keeping Procedure

The State Library has implemented a system to develop, maintain and retain WHS records that meet legislative requirements.

- Responsibilities:

At the State Library the Management Representative is responsible for ensuring that:

- There is an active Document and Record Keeping Procedure along with associated tools and resources in place and that they meet WHS and legislative requirements;

- All workers are trained and familiar with, have access to, and follow the procedure required for aspects of document and record keeping for which they are personally responsible for while working at The Edge Fabrication Lab;

- Others who are impacted by WHS at The Edge Fabrication Lab, such as additional departments are included in or consulted about document and record keeping at The Edge Fabrication Lab as required;

- Conduct review of the Document and Record Keeping Procedure as necessary.

- Informing workers and others about the requirement to appropriately record, store and manage WHSMS Manual information following the Document and Record Keeping Procedure;

- Adequately train all people in how to access, record, store and distribute WHSMS Manual information and documents in the workspace;

- Ensuring that suitable tools and resources are available to all workers to enable readily accessible and useful document and record keeping occur;

- Maintaining and managing documentation and records required by current WHS Legislation relating to WHS and worker’s compensation.

All workers are responsible for being aware of, understanding and following the Document and Record-Keeping Procedure when undertaking tasks involving workspace safety and the WHSMS Manual whilst working at the State Library.

Section 4 INCIDENT and HAZARD REPORTING

4.1 Incident Reporting

Objective: To identify and record all WHS incidents and near misses, whether or not these cause injury or damage, to minimise the potential for harm and to prevent recurrence.

Scope: This applies to everyone engaged to undertake tasks at the State Library workspaces/locations including independent contractors and volunteers.

An incident can include injury, illness, fatality, near miss, dangerous occurrence or breach of the QLD WHS Act.

The State Library is committed to reducing the frequency, impact and severity of incidents in the workspace, and to comply with legislative requirements regarding the notification and management of incidents.

All workers and any other affected person/s that are involved with or impacted by an incident at a The Edge Fabrication Lab workspace will be included in consultation and communication in relation to the incident

The State Library will also notify, manage and investigate any notifiable incidents in the workspace as determined by current QLD WHS Legislation.

The State Library will ensure the provision of coordinated incident reporting by implementing documented procedures for:

| * Emergency response and harm minimisation action; * Notification to relevant authorities of severe incidents/dangerous occurrence; * Incident reporting; * Incident investigation; * Consultation with related people (confidential where applicable); * Identification of causes; * Corrective and preventative actions; * Review of effectiveness of corrective/preventative actions; * Regular review of all incidents to identify any trends; * Report and action identified trends; * Meet legislative requirements for record keeping. |

4.2 Incident Reporting Procedure

- Responsibilities:

The State Library is responsible for ensuring that:

- There is an active procedure in place for the immediate response to and management of incidents;

- There is an Incident Reporting Procedure in place for the notification and management of incidents;

- All workers are trained and familiar with the Incident Reporting Procedure and have easy access to the report forms and procedure;

- State authority is notified immediately after becoming aware that a notifiable incident has occurred;

- So far as is reasonably practicable, that the workspace where any notifiable incident has happened is not disturbed until an inspector arrives at the workspace or any earlier time that an inspector directs;

- Conduct a review of the Incident Reporting procedure as required.

The Lead - Facilities operations is responsible for:

- Maintaining and reviewing the Incident Reporting Procedure as required;

- Train all workers in the Incident reporting procedure Assisting managers, supervisors and workers to follow the procedure when needed;

- Informing and consulting with the Work, Health and Safety Advisors (WHSA) and WHS Committee regarding incidents, in particular, notifiable incidents;

- Notification of notifiable incidents to the relevant regulator, within the prescribed timeframes;

- Ensure, so far as is reasonably practicable, that the workspace where the incident occurred is not disturbed until an inspector arrives at the workspace or any earlier time that an inspector directs;

- Maintaining records required by legislation relating to incidents.

Supervisors are responsible for:

- Informing workers and others (when applicable) about the requirement to report incidents promptly;

- Ensuring that the Incident Report Forms are readily accessible for workers;

- Complying with the Incident Reporting Procedure for incidents reported to them.

All workers are responsible for the initial reporting of incidents.

Procedure:

- Follow the State Library Emergency Response Procedure (see SLQ Emergency Response Plan) to care for workers, clear the incident area of people and secure to prevent further incident;

- Report all incidents as soon as possible to their immediate supervisor;

- When a reportable incident has occurred, Persons Responsible determines whether to preserve the workspace for investigation by the relevant regulator;

- Person involved in the incident completes an Incident Report Form;

- If the person involved in the incident is not able to complete the form, their immediate supervisor will compete it, in consultation with the involved person;

- Persons Responsible reports the incident to Management Representative, WHSA.

- Persons Responsible reports all notifiable incidents to the relevant authority, within the timeframe required by legislation;

- Persons Responsible keeps records of incidents and injuries by statutory requirements;

- Follow the incident investigation procedure, if as required.

4.3 Reporting

Objective: To provide direction for nominated persons to provide feedback via reports submitted to senior management on selected WHSMS elements.

Scope: This applies to all workers at The Edge Fabrication Lab, irrespective of their employment arrangements.

The State Library is committed to the provision of a functional and practical WHSMS and as such, understands the value maintaining feedback. The Edge Fabrication Lab will ensure effective reporting will take place via relevant individuals, including WHSA, HSR, affected workers, other duty holders/contractors to manage hazards and risks.

A proactive, planned and systematic approach to WHS reporting will help respond to change and improve health, safety and welfare outcomes. Reporting will be an on-going process conducted in line with the requirements of WHSMS and relevant legislation.

Reporting Procedure

Utilising consultative arrangements in place, and particular forms and tools, the Management Representative will report on all identified WHS issues, hazards, risks and legislated reportable incidents.

| Legislative | Non-legislative |

|---|---|

| * Injury reporting * Notifiable incidents * Worker’s compensation and return to work * Health monitoring and health surveillance * Reviews of risk controls * Consultative arrangements * Hazard Identification * Risk assessments * Other legislated matters as relevant (such as plant registration etc.) | * WHSMS performance * Results of audits * SLQ Incident reports and investigation * Preventative actions * Corrective actions |

Section 5 EMERGENCY MANAGEMENT

5.1 Emergency Management

Objective: To define the methods for managing the preparedness and response procedures for potential accidents and emergency situations that may lead to significant WHS impacts.

Scope: The Emergency Management applies to all people on The Edge Fabrication Lab workspaces. Encompass those on adjoining work workspaces, or private residences in The Edge Fabrication Lab emergency procedures and emergency responses (including evacuations) during significant or critical emergency situations or events.

The State Library will provide and maintain a safe environment for all people at the workspace and commits to preparing for potential WHS incidents and emergency situations which may arise. The procedures for preventing and mitigating emergency situations may include:

- Fires, explosions;

- Chemical spillage or leakage;

- Toxic emissions;

- Incidents as a result of equipment failure or human error;

- Medical Emergencies;

- Environmental incidents;

- Other relevant matters based on the nature of the work, hazards, size and location and number and composition of people at the workspace.

- Responsibilities:

The Management Representative is responsible for:

- Communication of policy and procedures around emergency response planning;

- Identifying who should participate in the initial risk assessment; and

- Provide guidance when necessary.

Work, Health and Safety Advisor:

- The WHSA will review the suitability and effectiveness of the emergency procedures after each accident or emergency situation.

Emergency Services Team is responsible for:

- The execution of the appropriate emergency procedures as advised;

- Ensuring the appropriate resources for the emergency response implementation are available;

- Attending emergency response as required;

- Ensuring communication of any changes is made known to Workers and any effected parties; and

- Participation in post emergency incident review processes.

Workers responsible for:

- Keeping informed and be familiar with the emergency response procedures;

- Attending any required training in relation to emergency response procedures; and

- Following the emergency procedures in case of an incident.

The Management Representative will ensure the health and safety of people by including the following:

| * Written instructions to contact emergency service organisations at the earliest opportunity; * Evacuation procedures and assembly points, firefighting and emergency equipment, marked at the workspace plan; * Building evacuation plans are displayed and not obstructed; * Emergency exits well-lit and clear of obstructions; * Fire protection equipment that is accessible and in working order; * Chemical spill containment equipment and clean up materials as appropriate; * SDS for all chemicals plus the chemical register available and current; * Trained first aid personnel and first aid equipment; * Roles and responsibilities designated and known, such as Area Wardens * Specialised training; * Specific procedures for mobility impaired persons; * Contact details for emergency services; * Consultation and co-operation with departments as applicable. |

5.2 First Aid

Objective: To minimise the adverse effects of an incident/injury by providing first aid resources and trained First Aid Officers (FAO).

Scope: This applies to all appointed FAO and any other relevant individuals at the workspace during work activities.

First aid is the provision of initial care for an illness or injury and consists of a series of simple and in some cases, potentially life-saving techniques with minimal equipment.

The Edge Fabrication Lab will use the guidelines as per relevant Code of Practice for First Aid to ensure the provision of a prompt, coordinated first aid response in these ways:

- Meet legislative requirements;

- Identify and assess the potential for an injury/incident occurring by:

- Observing tasks/work performed/work environment;

- Consulting with workers/HSR/Officers;

- Reviewing near misses and past incident reports;

- Reviewing SDS for hazardous chemicals;

- Determine suitable resources based on the nature of the work, hazards, size, location and number and composition of people at the workspace;

- Specify minimum requirements based on risk. E.g.:

- Type, contents and number of kits;

- Number and location of FAO (including remote locations);

- Appointing, training and replacing FAO as required. Provide FAO training by registered providers.

- [REF] First Aid Code of Practice 2014

5.3 First Aid Procedure

- All workers are informed and aware of the location of First Aid Kits;

- All workers are told and know the place and contact details for FAO;

- Regular audits of contents of First Aid Kit (including mobile kits) and contact details;

- The documentation of all treatment, injuries and illness;

- FAO:

- Receive adequate first aid and resuscitation training from a registered training organisation;

- Can perform first aid duties;

- Are willing to provide first aid treatment as required.

All workers will be provided access to first aid equipment and trained first aid personnel. An appropriate number of first aid personnel will be available at all times with consideration of:

- Number, location and content of equipment;

- First aid procedures;

- A number of required trained staff (including access for sub-contractors as needed). As per relevant Code of Practice for first aid equipment facilities and training for recommended number and placement of FAO;

- Signage (Design and use of first aid signs will be as per the relevant Australian Standard);

- No first aider will attempt first aid beyond their training or experience.

Location of first aid facilities and equipment detailed are on the applicable workspace evacuation plans.

Section 6 HAZARDOUS WORK

6.1 Electrical Safety

Objective: To reduce the risk of electrocution, electric shock or fires associated with the use of the electrical plant, equipment, appliances fixtures or fittings.

Scope: This applies to the risk from electric shock or electrocution to all workers, contractors, volunteers, members and visitors to The Edge Fabrication Lab workspace.

Electric shock can be received by either direct or indirect contact with an energised item, tracking through or across a medium (such as water), or by arching. Electrical burning and arching from equipment can also release toxic gases and air contaminants. Injuries from electricity can include muscular contraction (leading to falls if working at height, incidents if operating plant etc.), burns, cellular damage and death.

State Library is committed to protect workers and others from the risk of injury from the use of electricity, and from working in the vicinity of electricity. The Edge Fabrication Lab will put in place mechanisms to identify electrical hazards and risks arising from:

| * Maintenance and testing of electrical installations or equipment; * Changes or modifications to electrical installations or equipment; * The user of electrical equipment and the training and competency levels of users; * The age and condition of electrical installations or equipment; * Overhead and underground electrical services; * Electromagnetic fields; * Static electricity. |

All work on or near live or energised electrical installations and equipment requires a documented hazard identification and risk assessment.

Only licensed electricians may work on energised electrical equipment and only under strictly enforced SWMS and utilising suitable PPE and equipment.

6.2 Electrical Safety Procedure

- Responsibilities:

At the State Library the Management Representative is responsible for:

- Ensuring that any work involving the risk of electric shock or electrocution is identified and risk assessments completed and implemented as required and in compliance with the WHS/Electrical Legislation;

- Minimising the risk of electric shock or electrocution by ensuring that appropriate procedures and supporting mechanisms/systems are in place in respect of electrical hazards and risks at work;

- Ensuring that an appropriate emergency response and procedure are in place for incidents involving electricity;