Workflow Options

Order of Operations

The general order of operations is:

- Export design as PDF and DXF (if using another program)

- In CorelDraw, create new document using The Edge Standard or grab the template

- Import your design into CorelDraw (or create a new design)

- Check palette and colour settings (i.e. RGB)

- Convert all shapes to curves and group where appropriate

- Save Document

- Print from CorelDraw

- adjust print preferences in Rayjet Commander

- In mini manager

- Send job to laser

- Start cut from laser

For more detailed instructions, refer to The Edge laser cutter induction 1). Use The Edge Corel Draw settings.

CorelDraw

Why Use CorelDraw?

Trotec recommends the use of CorelDraw to design and/or as a final pre-cut check for the Rayjet. CorelDraw is popular in signwriting and laser cutter shops. This is the most common workflow in use at The Edge, and the only one available to new users. CorelDraw is available on the LaserCutter-PC and the Fabrication Lab laptops.

Importing Files in CorelDraw - Common Errors

The most common errors when importing external files into CorelDraw are; <datatables info=“false” paging=“false”>

| Problem | Solution |

|---|---|

| Missing or invisible lines | Export as DXF and PDF - try both |

| Lines the wrong colour | Select all and change line colour in Object Properties |

| Lines the wrong thickness | Select all and change line to hairline in Object Properties |

| Drawing scale is wrong | Export as DXF and PDF - try both, or rescale in CorelDraw |

Using Adobe Illustrator

Why use Illustrator?

- Extremely common graphic design software - most staff at The Edge have some familiarity, some are experts

- Defacto standard for vector design

It is an accessible resource at SLQ.

- The Edge DML has 16 licenses of the latest version of Illustrator

- The Fabrication Lab Laptops have Illustrator CS5 installed

- The Fabrication Lab Laser Cutter PCs have Illustrator CS5 installed

Illustrator Print Settings

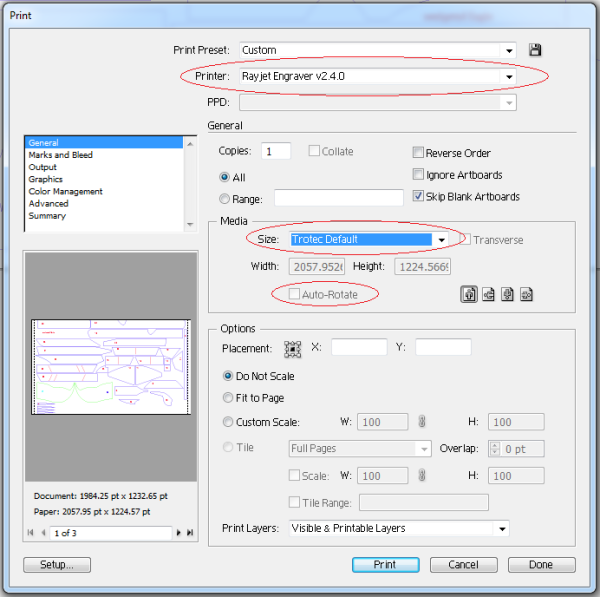

To cut from Ilustrator - after clicking the Print option in the File menu you will be prompted by the following screen:

The only thing you should need to change is the Media → Size option, choose Trotec Default. Selecting this option will automatically turn off Auto Rotate.

In order to access the RayJet Settings click Setup in the bottom left corner, click Preferences (The RayJet should already be selected for you). Once done, click Print and then Print again in order to send the file to the laser.

External Illustrator Resources

Very useful page for setting up your document and preparing to cut using Illustrator, including templates: CutLaserCut.com (Also has a CorelDraw, Inkscape and AutoCad section).

A Trotec Speedy 300 specific training document from the Faculty of Environmental Design at The University of Calgary.

Using Inkscape

Why Use Inkscape?

Free Open source and under active development, has a thriving community of users and developers. Cross platform (windows/mac/linux).

It is an accessible resource at SLQ.

- All Fabrication Lab Computers have Inkscape installed

External Resources

http://atxhackerspace.org/wiki/Using_Inkscape_with_the_Laser_Cutter

This is currently an untested technique! Please update if you do implement or test

Cutting from Fusion 360

Why cut from Fusion360?

- The Edge has an Education site License for the Autodesk Suite

- It is a full feature suite

- web based storage, with local offline editing

It is an accessible resource at SLQ.

- The Edge DML has 16 licenses of the latest version of Fusion360

- The Fabrication Lab Laptops have Illustrator CS5 Fusion360

- The Fabrication Lab Laser Cutter PCs have Illustrator CS5 Fusion360

Reasons Not To Use Fusion360?

Fusion360 does not use printers. So while Fusion360 has integrated CAM (Computer Aided Manufacturing) it is a complex procedure to set-up and out of scope for current laser cutter usage. Instead individual sketches must be exported as DXF files then loaded into CorelDraw.

This is an older post covering one technique from the autodesk forums.

Tip for lasercutting from here to export without construction lines.

What I usually do for getting things either laser cut or waterjet cut is to extrude my design from the original sketch which includes all the constraints, dimensions and construction lines. Then I create another sketch on the top surface of that extrusion and project all the extruded elements into that new sketch. That sketch is then exported into a DXF.

UPDATE 23/03/2017

Fusion360 has been extensively used to generate many DXFs for cutting without problems, using the recommended workflow.

Cutting from Autodesk

External Resources

Here is an in-house guide used by London Metropolitan University. This is Trotec specific - which is handy.

This is currently an untested technique! Please update if you do implement or test