~~REVEAL~~

Laser Cutter Inductions

In this induction you will learn how to safely operate our Rayjet300 Laser Cutter, making something to take home.

You will learn how to operate the machine, how to identify problems and what to do when problems occur.

This induction was prepared by Dan Cook in 2016

Requirements

- Participants must be over 16 years of age

- Enclosed, flat footwear must be worn at all times

- Please register for a State Library of Queensland patron account before you arrive. You will need an account to complete the induction, assessment and make bookings for the equipment

What’s a laser Cutter?

- Motorised mirror on an X, Y axis

- 100W Carbon Dioxide Laser

- Infrared follows VECTOR line work

- Can cut paper, card, wood, and acrylic

- Metal: can be etched only

- Wood: must check with the supervisor first

- Other Materials: see supervisor

Is it dangerous?

- Yes

- Fire Danger

- Laser Radiation

- Burns

- Blindness

- Safety Interlocks

- No user serviceable parts

Before you start

- Ask the supervisor to use the Laser Cutter

- Specify the material you want to cut… and the size

- Always ask the supervisor “Do we have a HOT WORK PERMIT?”

- No cutting can be done until the hot work permit is in place

- To stop the machine: Press the pause button or simply ift the lid…1)

Measure Twice, Cut Once!

- You know the size of your

- design, yes?

- You’ll need it!

It is critical that you know both the material thickness and the size of your material. Find out. Write it down.

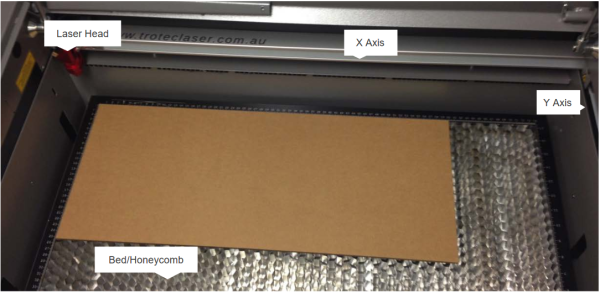

Inside the machine

Let’s start

Position the laser head

Check the focal distance

07.jpg 08.jpg 09.jpg

- Take the focus check

- device and place

- carefully into the

- channel on the side

- of the laser head…

- It’ll balance there.

- Don’t drop it!

Raise the bed... Carefully...

10.jpg

11.jpg

As the bed approaches the head, use individual button clicks to move the bed up until it JUST touches the focus device, either knocking it off or causing it to move.

Put it back where it lives!

12.jpg

Inside the front ledge of the machine!

Position the laser

13.jpg 14.jpg

Position the laser at the top left of the material to be cut. Do NOT adjust the height….

Shut the lid

15.jpg And move to the PC to setup the software

Open Corel Draw

16.jpg

Corel Draw

17.jpg

Object Properties

Colour Palette

Workspace

Toolbar

Menu bar

Select File > ‘New from Template’

18.jpg

Choose ‘edgetemplate.cdt’ Template

19.jpg

File > Import

20.jpg

Select your file…

21.jpg

Place the file in the top left corner

22.jpg

File is imported

23.jpg

Use the selection arrow

24.jpg This is used to select items within the program.

Use it to select the entire image by click-dragging a box over it.

Cut paths MUST have a RED Hairline

25.jpg

Check all cut lines are OK

26.jpg They should be a RED HAIRLINE

Add some text

27.jpg

Use your colours!

28.jpg Colours can be used to set cut, engrave or cut orders

Red Hairline – Cut

Engrave Power Setting Presets:

Colour

Red

Green

Blue

Red

255

0

0

Black

0

0

0

Blue

0

0

255

Desert Blue

51

102

153

Cyan

0

255

255

Green

0

255

0

Grass Green

0

153

51

Forest Green

0

102

51

File > Print

29.jpg

Go to ‘Preferences’ first

30.jpg

Setting up the Laser Cutter

31.jpg

Fire or fail!

BEWARE! Incorrect settings will cause a fire… Or a print fail… and you still pay for the materials

fire.png

Setting up the configuration

32.jpg Selected Material

Materials

Thickness

Set the material

33.jpg Click on Material

Select Type

Set the Thickness

34.jpg 35.jpg

Auto Focus is ALWAYS off

36.jpg 37.jpg Why? This machine does not have an auto focus system. Switching on this setting will cause a head crash. This is bad and will require a service technician to rectify.

Setup the cut…

38.jpg Always ON!

Colour Select

Power Setting

Fine Tune

Operation Type

Times to repeat

Speed <> Accuracy

What’s wrong here?

39.jpg

Check the settings…

40.jpg 500 DPI

Verify your settings

41.jpg Make sure this

is checked

Upload your settings

42.jpg Upload to printer

But…

43.jpg Never, ever, press this one!

When configured, hit OK!

44.jpg Leave these alone!

Send to the Print Manager

Now load the Print Manager

45.jpg Load the Print Manager

The Print Manager…

46.jpg Leave these alone!

The Print Manager…

46.jpg Select your print

Always use Move Job to Laser

46.jpg ALWAYS Check This!

47.jpg Did you check this?

Previews the operation

When previewing you should see the whole image with the colours you selected…

Press start on the laser cutter!

48.jpg 49.jpg

The Extractor

50.jpg 51.jpg Extractor Indicator

The HEPA grade air filter will extract all smoke. Ensure it has automatically come on by looking for this light…

The print job will start!

52.jpg 53.jpg 54.jpg

Keep watch!

Keep an eye on the cut in case of fire or issues with the print Usually, all engraving starts first, then the cutting In an emergency, lift the lid to stop the cut

Complete!

55.jpg 56.jpg The laser will move back to it’s home position.

BEFORE you lift the lid:

Use the keypad to lower the bed. This prevents damage to the head when removing material. Wait… at least 30 seconds for the smoke to clear

Carefully remove the work piece

57.jpg And you’re done!

Make sure you remove all cut material.

If some material has dropped into the honeycomb, alert the supervisor who will remove it for you.

Final Questions

What do you do if the lens is dirty? What do you do if the honeycomb is not located properly? What do you do if the work piece catches on fire? What do you do if the machine makes unusual noises?